- Results

- Crop

- Farm

- Location

+9.4% Wet Weight; +4.4% Dry Weight

Lactuca sativa L. ‘Coastal Star’ Romaine Lettuce

Santa Fe Community College Research Greenhouse

Santa Fe, NM, USA

+9.4% Yield Boost in Romaine Lettuce Trial

AT A GLANCE</h2

ABOUT THE PROJECT

Discover the future of agriculture with SFCC student Lydia Steinhoff’s groundbreaking study, guided by Professor Shultz and Manager Casas. Explore the growth of ‘Coastal Star’ romaine lettuce under UbiGro Inner 650 luminescent quantum dot (QD) greenhouse film versus a control film at Santa Fe Community College Research Greenhouse in 2022. Special thanks to UbiQD, Inc. for vital support.

Uncover the potential of Controlled Environment Agriculture and advanced greenhouse cover in revolutionizing crop cultivation. Ready to shape the future? Join us on this journey. College Research Greenhouse in 2022.

EXPERIMENT

UbiGro QD greenhouse films emitting at 650 nm were installed above a 254 ft2 (23.6 m2) nutrient film technique (NFT) system inside the Santa Fe Community College Research Greenhouse (SolaWrap cover, 83% PAR transmission). An identical neighboring NFT area in the greenhouse was chosen to serve as the control group, over which a clear polyethylene film (K50 Clear 6 mil, RKW Klerks) was installed to balance the light intensities and diffusivities between the two areas (see Table 1 describing the haze and transmission of the QD film and the polyethylene control film). A reflective mylar barrier was hung between to the two areas to prevent light mixing between treatment areas. A Watchdog Plant Growth Micro Station with four quantum light sensors was installed to measure daily light integral (DLI) on each side of the experiment using five-minute measurement spacings. Crops were grown with Calcium Nitrate, Magnesium Sulfate, and Potassium Nitrate-rich nutrient salt solutions with targets of EC 1.7 and pH 5.8. In order to better achieve proper light intensity for lettuce, shade curtains were deployed over the crops in both treatments.

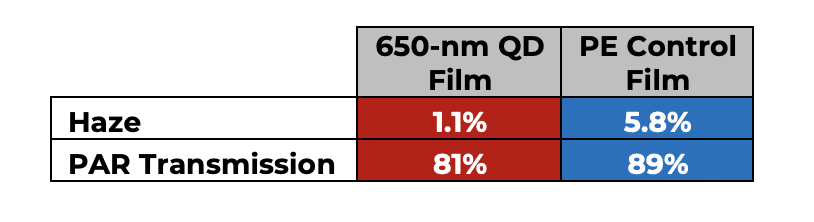

Table 1. Optical properties of experimental films. Haze and PAR transmission of the QD film and the polyethylene control film.

Over an 11-week period spanning July to October 2022, two seven-week crops were grown. Each crop consisted of 72 plants, including 36 plants per experimental group. Seeds were sown in Oasis Rootcubes on an ebb-and-flow seedling table inside the greenhouse. Each pair of plant groups was transplanted into the NFT system, under the QD film and control films, at approximately three weeks after sowing. The harvest times ranged from 45 days after sowing (DAS) to 50 DAS. The first harvest was completed on September 8, 2022, and the final harvest was completed on October 6, 2022.

HARVEST DATA

Due to labor scheduling, critical activities including sowing and harvesting were conducted ±4 days from the target nominal DAS, so days after treatment (DAT) were kept consistent between experimental repeats. The maturity time for this lettuce cultivar is 57 DAS, according to seed purveryer Johnny’s Seeds; however, this 57-day maturity time can vary with sunlight intensity, seasonality, climate, and other variables, which can be better controlled in a greenhouse. These maturities at harvest represent typical harvest times for a commercial greenhouse grower.

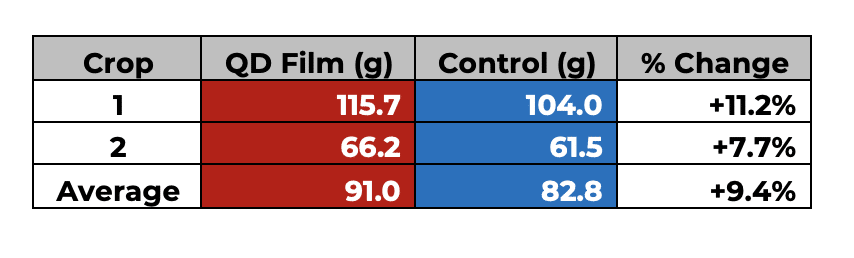

Table 2. Average wet weights. Harvested wet weights, and % changes for lettuce harvests across experimental repeats. Positive % change values indicate greater performance under the treatment.

Average wet weights for each harvest were compared across both crops, and are shown in Table 2 and in the form of bar plots in Figure 1. Harvest data outside of three standard deviations from the mean were consdired outliers; no data qualified as outliers by this definition, so all data collected were included in the analysis. Plants grown under the QD film exhibited larger wet weights in each experimental repeat. Greater yield differences (i.e., increases) were observed under the QD film treatment when plants overall were larger as in the first experimental repeat where +11% more fresh weight was accumulated under the QD film.

The larger growth results represent the most impactful results of this experiment, as a commercial grower would grow out their crop to a marketable wet weight of ~100 to 150 g and would realize the yield benefit in terms of greater revenue (if selling by weight or size) or faster grow cycles (if selling by head count). This yield boost for the mature crop translated to the ability to harvest the same size crop 2-3 days earlier, which would compound to approximately one extra harvest cycle annually.

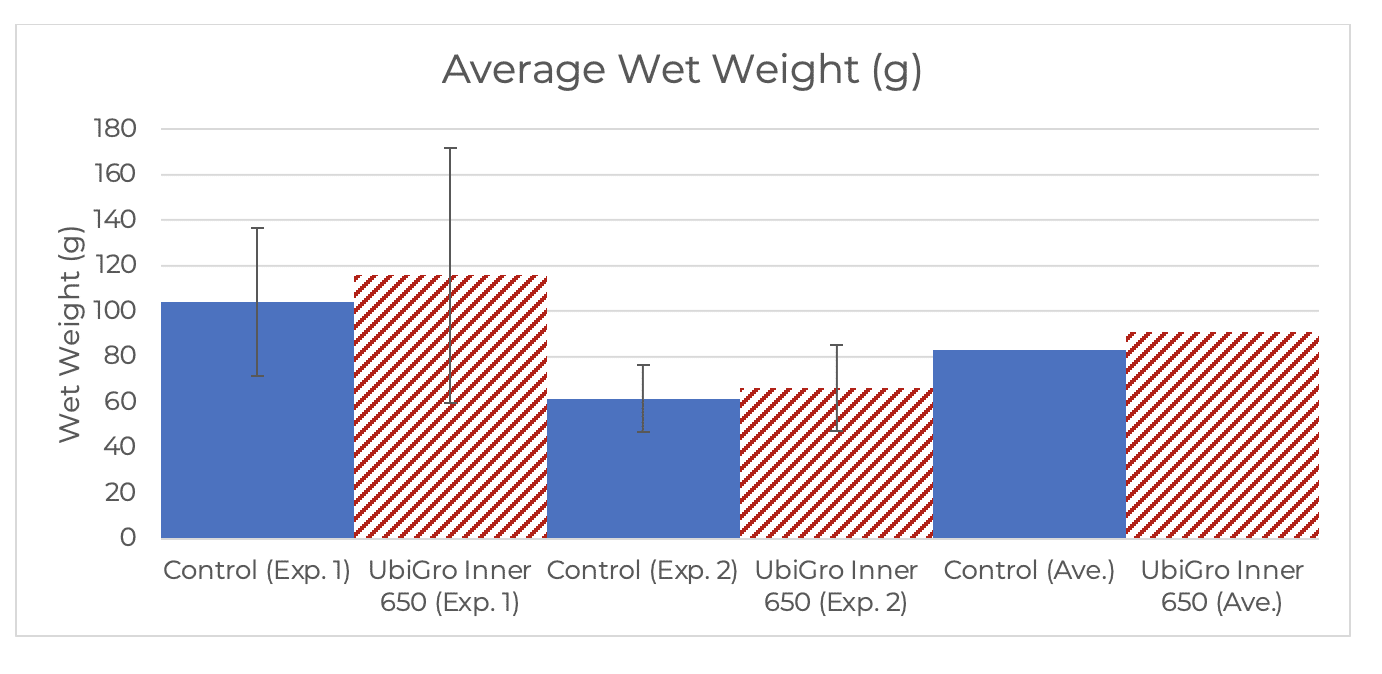

Figure 1. Average wet weight. Average wet weights measured at 28 DAT in each experimental repeat and overall, with 1 standard deviation error bars.

In this study, planting density was cut to approximately half-size from previous lettuce experiments in this NFT system to reduce shading by neighboring plants and thereby decrease variance; however, large variances remained, and larger variances were present in the treatment group in both experimental repeats. The persistent variance could have resulted from a number of factors, including the difference in cumulative light integral between experimental repeats. Harvest data from one week earlier indicated a lower magnitude of the treatment effects even one week earlier than these harvest data collected at maturity; more data on a larger scale could further clarify this result.

The larger growth results represent the most impactful results of this experiment, as a commercial grower would grow out their crop to a marketable wet weight of ~100 to 150 g and would realize the yield benefit in terms of greater revenue (if selling by weight or size) or faster grow cycles (if selling by head count). This yield boost for the mature crop translated to the ability to harvest the same size crop 2-3 days earlier, which would compound to approximately one extra harvest cycle annually.

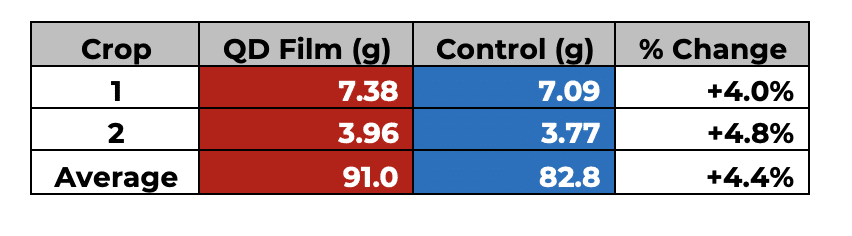

Table 3. Average dry weights. Harvested dry weights and % changes for lettuce harvests across experimental repeats. Positive % change values indicate greater performance under the treatment.

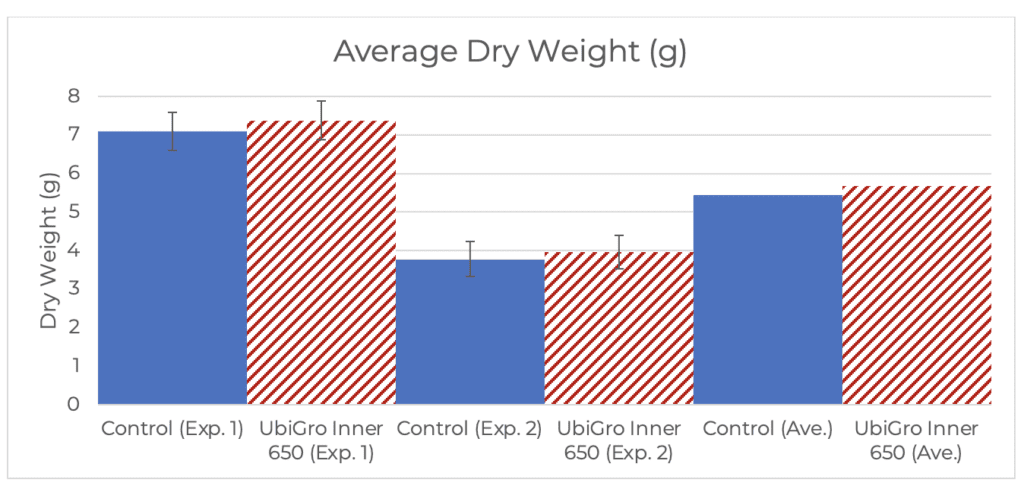

Average dry weights for each harvest were compared across both crops, and are shown in Table 3 and in the form of bar plots in Figure 2. Harvest data outside of three standard deviations from the mean were considered outliers; no data qualified as outliers by this definition, so all data collected were included in the analysis. Plants grown under the QD film exhibited larger wet weights in each experimental repeat.

Figure 2. Average dry weight. Average dry weights measured at 28 DAT in each experimental repeat and overall, with 1 standard deviation error bars.

Relatively greater increases in yield were observed under the QD film treatment when plants overall were smaller as in the second experimental repeat where +4.8% more dry weight accumulated under the QD film. Interestingly, the trend in dry weight is the opposite of the trend in wet weight as overall plant size increases. This greater improvement in dry weight at smaller overall sizes could be due to a greater proportion of the plant being water weight as the plants increase in overall size, indicating that the QD film may facilitate the input of water into the plant as it grows.

Daily Light Integral

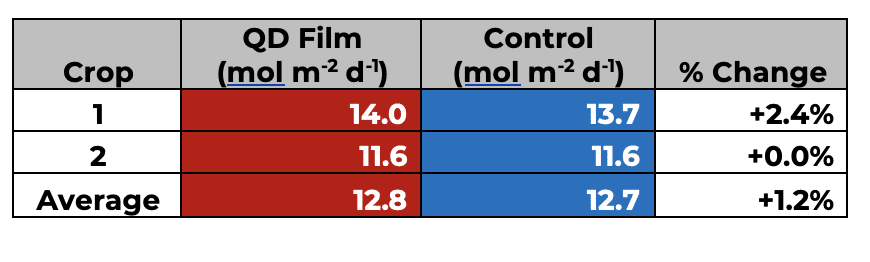

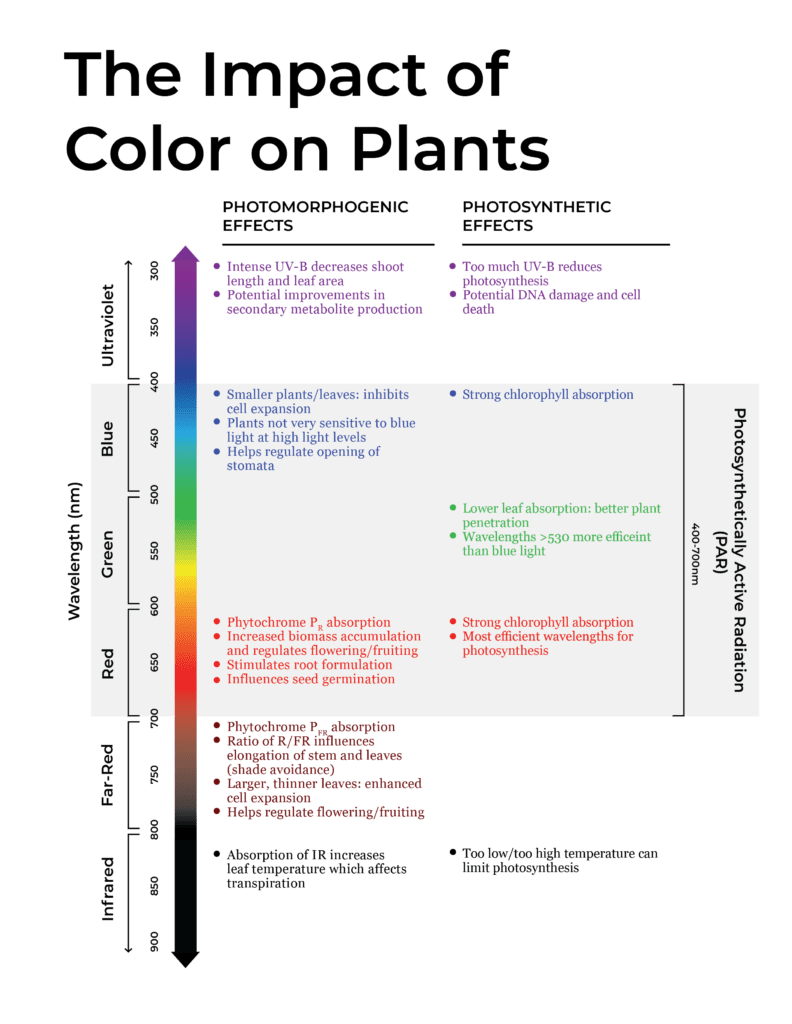

Light intensity balance was important to quantify in this trial in order to isolate the effects of spectral quality. The two sides of the trial must balance light intensity as closely as possible in order to provide comparable results. Daily light integral (DLI) describes the number of photons in the photosynthetically active range (PAR, 400-700 nm) that are delivered per unit area over a 24-hour period, and is the typical cumulative metric for measuring light intensity over crops. Average DLI values for the QD film and control groups are plotted below in Table 4.

Table 4. Average treatment DLIs. Average DLIs measured during treatment periods below the films across experimental repeats. Positive % change values indicate greater light intensity under the treatment.

Seasonal and daily geometric changes in weather and sun angle interacting with the infrastructure of the greenhouse caused DLI differences to vary as the season changed from summer to winter. The first experimental repeat experienced a higher average DLI of 13.7 mol m-2 d-1 throughout the treatment period than the second experimental repeat with only 11.6 mol m-2 d-1. While the average DLIs under the shade curtains were suboptimal for lettuce growth, these DLIs were more appropriate for healthy lettuce growth than the average DLIs measured above the films during these periods (28.2 and 27.1 mol m-2 d-1 for repeats 1 and 2, respectively).

As is the case in all experiments studying spectral quality, it was important in this study to isolate the effect of spectral differences from the effect of light intensity.

In a light-intensity regime optimal for a specific crop, keeping the PPFD balanced within a 5% difference between experimental groups is ideal. During the first experimental repeat, the plants experienced +2.4% greater DLI under the QD film, whereas the plants experienced equivalent DLI under both films during the second repeat. Overall the experiment was tighly balanced with only +1.2% greated DLI under the QD film across both repeats. Balancing the light intensities so closely enabled this study to isolate the effect of spectral quality from light intensity with a high confidence.

Conclusion

This study exhibited that UbiGro Inner 650 quantum dot luminescent greenhouse films applied over Coastal Star romaine lettuce increased yields in both wet weight (+9.4% average increase) and dry weight (+4.4% average increase), allowing growers to achieve faster crop turnover (~2-3 days quicker) and higher productivity in the greenhouse. This greater productivity enables growers to squeeze in another crop cycle per year or come to market with larger crops, depending on their preference.

Achieving statistically significant results is challenging with biological variance and limited scope, so larger commercial trials are needed to clarify and further validate the results observed here.

Share:

Talk to a greenhouse lighting expert today!

Connect With Us

Company

Resources

Hunter McDaniel, PhD

Founder & CEO

Hunter earned a Ph.D. in Materials Science and Engineering at the University of Illinois at Urbana-Champaign, before joining Los Alamos National Laboratory in the Chemistry Division. Ultimately the value proposition of UbiGro is about boosting crop yields and quality without the cost or energy impact of lighting. Hunter has more than fifty publications and patents, and more than 2000 total citations, h-index: 20. Hunter fundamentally believes that novel materials underpin every significant technology advancement, and he is focused on leveraging new materials to have a lasting and sustainable impact.

Damon Hebert, PhD

Director of Agriculture

Damon brings a wide range of experience in agriculture, materials science, spectroscopy, and small business. During his time in Prof. Angus Rockett’s research group at The University of Illinois at Urbana-Champaign (UIUC), Hebert authored a doctoral thesis and multiple papers on the materials science of CIGS semiconductor materials, which is closely related to the materials developed at UbiQD. He also served as a consultant to Nanosolar, a CIGS nanocrystal solar cell manufacturing company. Hebert has industry experience having co-founded Dr. Jolly’s, a leading cultivation and distribution operation in Bend, OR.

Tania Lafaille

Sales Representative

Tania is a UbiGro Sales Representative, with over 7 years of experience in product sales (specifically berries and avocados) covering all of North America and parts of South America. While in agriculture, Tania has cultivated strong relationships with growers and distributors, granting her a unique insight into both perspectives. That understanding, paired with her fierce dedication to results, drives her fun and fiery commitment to her craft. Tania is based in Gilroy, CA.

Tyler Veyna

Sales Representative

Tyler brings 15 years of experience in Greenhouse production and facility management of a wide range of crops in multiple states to the UbiGro team. Based in Salinas, California. “Being a fourth-generation farmer, I look to improve and empower the grower, and with UbiGro, we can do just that.”

Jim Gideon

Sales Manager

Jim Gideon is an UbiGro Sales Manager, with over 25 years of greenhouse industry sales experience covering all of North America. Previously Jim has worked for Green Tek, Plazit-Polygal, Texel, Cherry Creek, and Nexus. He is based in Montgomery, AL, and Jim believes that “light is everything to the grower.”

Eric Moody

Director of Sales

Eric Moody is UbiQD’s Director of UbiGro Sales. Eric has more than 6 years of experience in horticulture lighting industry, building relationships with greenhouse growers of all sizes and crops on optimal lighting for their growing operation, and most recently managed a North American sales team for PL Light Systems. Overall, Eric has been in sales leadership positions for more than 13 years. Eric brings with him a great understanding of the market and available technologies for growers, greenhouse facilities, and sales leadership. Reach Eric by phone at 541-490-6421 or by email at [email protected].

Mike Burrows, PhD

Dr. Michael Burrows is UbiQd’s Vice President of Business Development. His educational background includes a Materials Science doctorate from the University of Delaware and an MBA from Duke University Fuqua School of Business. His career has specialized in the commercialization of novel electronic materials in venture-run programs for different industries including solar, biosensors, and the automotive industry. In both start-up and corporate environments, he has extensive experience in global market development, foraging supply chain partnerships, productization, and brand building. He is currently leading UbiQD’s partnership efforts in luminescent greenhouse technology, smart windows, and security ventures.

Matt Bergern, PhD

Cheif Product Officer

As Chief Product Officer at UbiQD, Dr. Matt Bergren leads the company’s product development efforts, sales, and product manufacturing, including the company’s first commercial agriculture product, UbiGro. He plays a critical role in continuing the company’s path of technology development and vision of powering product innovations in agriculture, clean energy, and security.

He serves as the principal investigator for UbiQD’s contract with NASA, focused on tailoring the solar spectrum for enhanced crop production for space missions. Dr. Bergren’s leadership experience includes serving on the board of directors for the New Mexico Energy Manufacturing Institute, focused on job creation in New Mexico’s energy, and related manufacturing community.