+27% Yield Boost in Microgreens Trial: Enhancing Microgreens Yield

AT A GLANCE</h2

- Results

- Crop

- Farm

- Location

+27% Wet Weight at maturity; +14% seedling density

Mizuna and Braising mix (microgreens)

Kunia Country Farms

Kunia, Oahu, HI, USA

ABOUT THE PROJECT

This study, locally known as the ‘Glow and Grow’ project, monitored the growth and development of two aquaponic microgreen crops: mizuna (a Japanese mustard green) and a 7-crop braising mix. These crops were grown under an orange-red UbiGro luminescent quantum dot (QD) greenhouse film, significantly boosting the micro grow yield. Identical crops were grown in a control area without a QD film, showcasing the effective farming microgreens techniques utilized in the project.

Figure 1. QD film installation at Kunia Country Farms on the island of Oahu, Hawaii.

EXPERIMENT

At Kunia Country Farms in Oahu, Hawaii, UbiGro QD greenhouse films emitting 600 nm were installed above 3,200 ft2 (297 m2) of aquaponic floating raft tabletop grow beds, sheltered with an open-sided polycarbonate greenhouse cover structure. An identical neighboring area in the greenhouse was chosen to serve as the control group, where no QD films were installed. Crops, focusing on farming microgreens, were grown using the farm’s standard aquaponic nutrients.

Figure 2. QD films were installed above aquaponic float grow beds in Oahu, Hawaii. Above the film is the polycarbonate greenhouse roof.

Harvest datasets were collected from April through November, covering nine different harvests; over 74 flats of crops were harvested. For wet weights, flats (2’x4′) of mature microgreens from both sides of the experiment were randomly chosen, photographed, cut at the stem, bagged, and weighed, following the farm’s standard harvest procedures. Spectra were recorded during install week to quantify the color-shifting effects of the QD films on the sunlight spectrum and assess the microgreens yield improvements.

HARVEST DATA

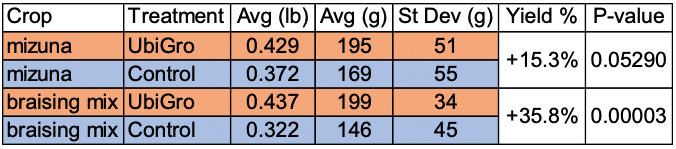

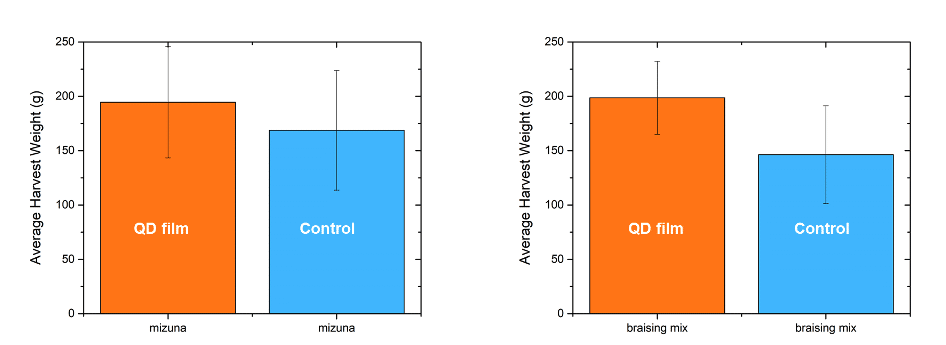

Plants grown under the QD film exhibited larger wet weights for every mizuna and braising mix harvest. Average wet weights for each harvest are shown in Table 1, and in the form of bar plots is in Figure 3. The average wet weight yield increase was +15.3% for mizuna and +35.8% for braising mix. Taken together, the yield improvement across both crops was +27%.

These micro greens are fast turnaround crops taking just two weeks from seeding to harvest. The yield increases observed here could be converted into faster turnaround if the grower would rather have the exact yield in less time. In this case, mizuna could be harvested ~2 days earlier than if the QD film was not used, and the braising mix could be gathered ~5 days earlier. The harvest results were analyzed with a t-Test (two-sample assuming unequal variances), and corresponding p-values are shown in Table 1.

This analysis showed that the yield improvements observed for both crops were statistically significant beyond a 95% confidence threshold, meaning that the difference was highly likely to be a result of an existing relationship: namely, the spectral change and diffusion of sunlight caused by the QD film.

Table 1. Harvest data for two types of microgreens grown under UbiGro QD films and without (control) across nine different harvests in 2022.

Figure 3. Average wet weight yields for harvested flats of microgreens throughout the experiment.

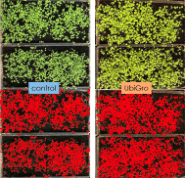

Photos are shown below that exemplify the yield differences.

Figure 4. Top: mizuna flats photographed in profile. Bottom: braising mix flats photographed in profile.

Figure 5. Left: mizuna flats photographed from overhead. Right: braising mix flats photographed from overhead.

Economic Impact of Yield Increase

The economic impact of the QD film can be evaluated by comparing the value of the microgreens yield increase to the cost and the lifetime of UbiGro. Let’s take a single 4′ x 100′ tabletop grow bed as an example. This 400 ft2 area regularly produces 100 lbs of microgreens each harvest, or 2,600 lbs each year (bi-weekly harvest). The farms sell microgreens at $6/lb wholesale, so the table produces $15,600/year in revenue. A +27% micro grow yield boost for the same area would produce an extra $4,212/year/table. Per square foot, that’s an additional +$10.53/ft2/year. The grower estimates a nearly 100% gross margin on the excess production since there is no extra seed or labor cost.

Now we must compare this extra revenue to the cost of the QD film, which is $3/ft2 + shipping and installation, or $4/ft2 as an estimated installed cost. The excess yearly revenue due to the yield increase exceeds the cost of the film. This corresponds to a super fast payback time of just 4.5 months. The QD film has a lifetime of 4+ years in a greenhouse. The QD film will realize profits for the greenhouse over 3.5 years after it has been paid back. UbiGro is an excellent fit for Hawaiian microgreens, increasing greenhouse cultivation’s sustainability and profitability. Many local factors contribute to this: (1) year-round sun, (2) high sun intensity, (3) high produce prices, and (4) high electric costs making lighting impractical. Farming microgreens in such an environment clearly illustrates the significant advantages.

Seedling Imaging

Another dataset was recorded at Kunia Country Farms to assess the QD film’s impact on microgreens yield and seedling germination and growth. After one week, high-resolution overhead photos of mizuna seedling flats were captured randomly from each side of the experiment, reflecting on micro grow yield. Images were processed in Image-J using the Color Threshold tool to quantify the amount of seedling leaf area in each photo, important in farming microgreens. Examples of these photos are shown in Figure 6 below.

Figure 6. Overhead photos of mizuna seedlings at 1 week maturity. Top row: Raw photos; Bottom row: processed photos in ImageJ, where the red area is calculated as seedling area. Seedling areas from the control and UbiGro sides are compared. In this photoset, the relative difference was +33% more leaf are on the UbiGro side.

Over three different datasets taken from September to November, the aggregate difference in seedling leaf area was +14.4% in favor of the UbiGro side. This evidence suggests that the QD film assists in seedling germination and development, and this benefit is seen at least 1 week prior to harvest.

Share:

PMI Project of the Year

In December 2022, the ‘Glow and Grow’ project, focused on enhancing microgreens yield through innovative techniques, along with partner Kamehameha Schools, was awarded the Project of the Year by the Project Management Institute of Hawaii for its exceptional contributions to farming microgreens. We are so proud to be recognized! Learn more about this recognition below.

Talk to a greenhouse lighting expert today!

Connect With Us

Company

Resources

Hunter McDaniel, PhD

Founder & CEO

Hunter earned a Ph.D. in Materials Science and Engineering at the University of Illinois at Urbana-Champaign, before joining Los Alamos National Laboratory in the Chemistry Division. Ultimately the value proposition of UbiGro is about boosting crop yields and quality without the cost or energy impact of lighting. Hunter has more than fifty publications and patents, and more than 2000 total citations, h-index: 20. Hunter fundamentally believes that novel materials underpin every significant technology advancement, and he is focused on leveraging new materials to have a lasting and sustainable impact.

Damon Hebert, PhD

Director of Agriculture

Damon brings a wide range of experience in agriculture, materials science, spectroscopy, and small business. During his time in Prof. Angus Rockett’s research group at The University of Illinois at Urbana-Champaign (UIUC), Hebert authored a doctoral thesis and multiple papers on the materials science of CIGS semiconductor materials, which is closely related to the materials developed at UbiQD. He also served as a consultant to Nanosolar, a CIGS nanocrystal solar cell manufacturing company. Hebert has industry experience having co-founded Dr. Jolly’s, a leading cultivation and distribution operation in Bend, OR.

Tania Lafaille

Sales Representative

Tania is a UbiGro Sales Representative, with over 7 years of experience in product sales (specifically berries and avocados) covering all of North America and parts of South America. While in agriculture, Tania has cultivated strong relationships with growers and distributors, granting her a unique insight into both perspectives. That understanding, paired with her fierce dedication to results, drives her fun and fiery commitment to her craft. Tania is based in Gilroy, CA.

Tyler Veyna

Sales Representative

Tyler brings 15 years of experience in Greenhouse production and facility management of a wide range of crops in multiple states to the UbiGro team. Based in Salinas, California. “Being a fourth-generation farmer, I look to improve and empower the grower, and with UbiGro, we can do just that.”

Jim Gideon

Sales Manager

Jim Gideon is an UbiGro Sales Manager, with over 25 years of greenhouse industry sales experience covering all of North America. Previously Jim has worked for Green Tek, Plazit-Polygal, Texel, Cherry Creek, and Nexus. He is based in Montgomery, AL, and Jim believes that “light is everything to the grower.”

Eric Moody

Director of Sales

Eric Moody is UbiQD’s Director of UbiGro Sales. Eric has more than 6 years of experience in horticulture lighting industry, building relationships with greenhouse growers of all sizes and crops on optimal lighting for their growing operation, and most recently managed a North American sales team for PL Light Systems. Overall, Eric has been in sales leadership positions for more than 13 years. Eric brings with him a great understanding of the market and available technologies for growers, greenhouse facilities, and sales leadership. Reach Eric by phone at 541-490-6421 or by email at [email protected].

Mike Burrows, PhD

Dr. Michael Burrows is UbiQd’s Vice President of Business Development. His educational background includes a Materials Science doctorate from the University of Delaware and an MBA from Duke University Fuqua School of Business. His career has specialized in the commercialization of novel electronic materials in venture-run programs for different industries including solar, biosensors, and the automotive industry. In both start-up and corporate environments, he has extensive experience in global market development, foraging supply chain partnerships, productization, and brand building. He is currently leading UbiQD’s partnership efforts in luminescent greenhouse technology, smart windows, and security ventures.

Matt Bergern, PhD

Cheif Product Officer

As Chief Product Officer at UbiQD, Dr. Matt Bergren leads the company’s product development efforts, sales, and product manufacturing, including the company’s first commercial agriculture product, UbiGro. He plays a critical role in continuing the company’s path of technology development and vision of powering product innovations in agriculture, clean energy, and security.

He serves as the principal investigator for UbiQD’s contract with NASA, focused on tailoring the solar spectrum for enhanced crop production for space missions. Dr. Bergren’s leadership experience includes serving on the board of directors for the New Mexico Energy Manufacturing Institute, focused on job creation in New Mexico’s energy, and related manufacturing community.