The Science of Agricultural Covers: Boosting Plant Growth Potential

Controlled environments have revolutionized agriculture by extending growing seasons and improving plant yields. While high-tech structures exist, such as glass-glazed greenhouses, other low-tech options like tunnels and hoophouses are less costly to build and require covers.

A cover material is central to efficient plant growth, playing crucial roles in managing light, heat, moisture, and resulting plant health. This blog discusses the range and scientific principles behind various cover materials including polycarbonate, plastic, and UbiGro covers, to understand their operating efficiency and impacts on plant growth.

Light Transmission: Illuminating Plant Growth

Light Transmission: Illuminating Plant GrowthA primary function of covers is to regulate light transmission. Different materials have distinct properties that affect the amount and type of light that crops receive.

Polycarbonate Panels: Provides ample light transmission and better insulation compared to plastic covers. They often include UV protection layers to prevent degradation and prolong working timespan.

Plastic Films: These covers, typically made from polyethylene or similar polymers, have varying levels of light transmission depending on their thickness and additives. Some plastic films actively block UV rays, while others evenly diffuse light to reduce shadows and promote uniform plant growth.

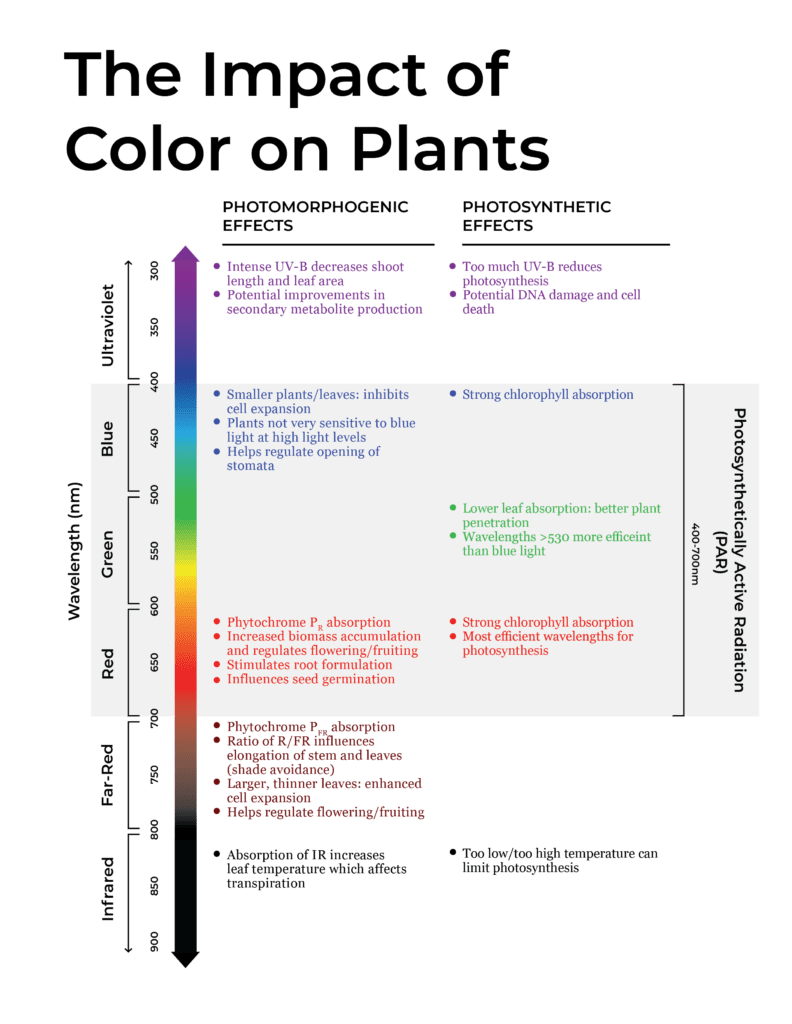

UbiGro Covers: UbiGro covers use advanced materials to enhance the light for plant growth. These covers utilize photoluminescent technology to convert UV and blue light into red and orange wavelengths, which are more efficient for photosynthesis. This results in improved plant growth, increased yields, and sped up life cycles for quicker crop turnover.

Heat Retention: The Greenhouse Effect in Action

Greenhouses work by trapping heat, a process known as the greenhouse effect. Cover material significantly influences heat retention in plant growth environments.

Polycarbonate Panels: Highly efficient at heat retention due to their insulating properties. Multi-wall polycarbonate panels create air pockets between the layers, which act as a buffer to reduce heat transfer from inside to outside of the structure. This design makes polycarbonate panels especially suitable for colder climates.

Plastic Films: Lightweight and can retain heat effectively, though they may need replacement every few years due to wear and tear. Innovations in plastic films have led to materials that better trap infrared radiation, enhancing heat retention.

UbiGro Covers: Lightweight and have similar heat retention to plastic films.

Moisture Control: Balancing Humidity and Condensation

Maintaining optimal humidity levels is crucial for plant health and water usage, affecting plant disease pressure, and water evapotranspiration from leaves and substrate. Choice of cover material impacts moisture control within the greenhouse.

Polycarbonate Panels: Less prone to condensation due to their insulation properties. Some panels come with anti-fog treatments to prevent moisture accumulation.

Plastic Films: Often include anti-drip coatings that reduce condensation buildup. They can also regulate humidity by allowing controlled water vapor permeability.

UbiGro Covers: Include anti-condensate additive to prevent condensation.

Durability & Longevity: Choosing for the Long Haul

The lifespan of greenhouse cover materials varies based on their composition and environmental exposure.

Polycarbonate Panels: Known for their durability and resistance to impact, polycarbonate panels can last up to 10 years or more. They require minimal maintenance and are less likely to degrade under UV exposure.

Plastic Films: These are cost-effective but have a shorter lifespan, typically lasting 1-4 years depending on the material quality and environmental factors such as UV radiation exposure, extreme temperatures, wind, and physical wear from handling or installation. UV-stabilized films can extend their lifespan.

UbiGro Covers: Similar lifespan, durability, and cost-effectiveness of plastic films.

Conclusion

Selecting the right cover material is essential for optimizing plant growth and operational efficiency. To aid in decision-making, here is a brief comparison of the pros and cons of each material:

- Polycarbonate Panels:

- Pros: Good insulation, durable, impact-resistant, longer lifespan (10+ years)

- Cons: Higher initial cost, can yellow over extended periods

- Plastic Films:

- Pros: Lightweight, cost-effective, customizable light diffusion.

- Cons: Susceptible to UV degradation, shorter lifespan (1-4 years)

- UbiGro Covers:

- Pros: Enhanced light spectrum aids in plant growth, lightweight, durable

- Cons: Relatively new technology, availability may vary

By understanding the science behind light transmission, heat retention, moisture control, and durability, greenhouse operators can make informed choices that best suit their specific agricultural needs.

Looking to Enhance Your Greenhouse:

If you’re looking to enhance your greenhouse’s efficiency and maximize your yields, consider exploring UbiGro covers. Their innovative technology not only enhances the quality of sunlight your plant receives for optimal photosynthesis but also ensures durability and effective heat retention, making them a smart investment for modern greenhouse operations. Take the next step in optimizing your greenhouse — contact us for more details and to get started with UbiGro covers!

Eric Moody

Eric Moody is UbiQD's Director of UbiGro Sales. Eric has more than 8 years of experience in the horticulture lighting industry, building relationships with greenhouse growers of all sizes and crops on optimal lighting for their growing operation, and most recently managed a North American sales team for PL Light Systems. Overall, Eric has been in sales leadership positions for more than 17 years. Eric brings with him a great understanding of the market and available technologies for growers, greenhouse facilities, and sales leadership.

Share:

Connect With Us

Company

Resources

Hunter McDaniel, PhD

Founder & CEO

Hunter earned a Ph.D. in Materials Science and Engineering at the University of Illinois at Urbana-Champaign, before joining Los Alamos National Laboratory in the Chemistry Division. Ultimately the value proposition of UbiGro is about boosting crop yields and quality without the cost or energy impact of lighting. Hunter has more than fifty publications and patents, and more than 2000 total citations, h-index: 20. Hunter fundamentally believes that novel materials underpin every significant technology advancement, and he is focused on leveraging new materials to have a lasting and sustainable impact.

Damon Hebert, PhD

Director of Agriculture

Damon brings a wide range of experience in agriculture, materials science, spectroscopy, and small business. During his time in Prof. Angus Rockett’s research group at The University of Illinois at Urbana-Champaign (UIUC), Hebert authored a doctoral thesis and multiple papers on the materials science of CIGS semiconductor materials, which is closely related to the materials developed at UbiQD. He also served as a consultant to Nanosolar, a CIGS nanocrystal solar cell manufacturing company. Hebert has industry experience having co-founded Dr. Jolly’s, a leading cultivation and distribution operation in Bend, OR.

Tania Lafaille

Sales Representative

Tania is a UbiGro Sales Representative, with over 7 years of experience in product sales (specifically berries and avocados) covering all of North America and parts of South America. While in agriculture, Tania has cultivated strong relationships with growers and distributors, granting her a unique insight into both perspectives. That understanding, paired with her fierce dedication to results, drives her fun and fiery commitment to her craft. Tania is based in Gilroy, CA.

Tyler Veyna

Sales Representative

Tyler brings 15 years of experience in Greenhouse production and facility management of a wide range of crops in multiple states to the UbiGro team. Based in Salinas, California. “Being a fourth-generation farmer, I look to improve and empower the grower, and with UbiGro, we can do just that.”

Jim Gideon

Sales Manager

Jim Gideon is an UbiGro Sales Manager, with over 25 years of greenhouse industry sales experience covering all of North America. Previously Jim has worked for Green Tek, Plazit-Polygal, Texel, Cherry Creek, and Nexus. He is based in Montgomery, AL, and Jim believes that “light is everything to the grower.”

Eric Moody

Director of Sales

Eric Moody is UbiQD’s Director of UbiGro Sales. Eric has more than 6 years of experience in horticulture lighting industry, building relationships with greenhouse growers of all sizes and crops on optimal lighting for their growing operation, and most recently managed a North American sales team for PL Light Systems. Overall, Eric has been in sales leadership positions for more than 13 years. Eric brings with him a great understanding of the market and available technologies for growers, greenhouse facilities, and sales leadership. Reach Eric by phone at 541-490-6421 or by email at [email protected].

Mike Burrows, PhD

Dr. Michael Burrows is UbiQd’s Vice President of Business Development. His educational background includes a Materials Science doctorate from the University of Delaware and an MBA from Duke University Fuqua School of Business. His career has specialized in the commercialization of novel electronic materials in venture-run programs for different industries including solar, biosensors, and the automotive industry. In both start-up and corporate environments, he has extensive experience in global market development, foraging supply chain partnerships, productization, and brand building. He is currently leading UbiQD’s partnership efforts in luminescent greenhouse technology, smart windows, and security ventures.

Matt Bergern, PhD

Cheif Product Officer

As Chief Product Officer at UbiQD, Dr. Matt Bergren leads the company’s product development efforts, sales, and product manufacturing, including the company’s first commercial agriculture product, UbiGro. He plays a critical role in continuing the company’s path of technology development and vision of powering product innovations in agriculture, clean energy, and security.

He serves as the principal investigator for UbiQD’s contract with NASA, focused on tailoring the solar spectrum for enhanced crop production for space missions. Dr. Bergren’s leadership experience includes serving on the board of directors for the New Mexico Energy Manufacturing Institute, focused on job creation in New Mexico’s energy, and related manufacturing community.