The Status of the Global Greenhouse Industry

The global greenhouse industry, a vital component of the agricultural sector, is experiencing rapid growth in greenhouse farming and is anticipated to maintain this trajectory in the upcoming year. This surge is primarily driven by an escalating demand for fresh produce and the increasing adoption of controlled environment agriculture by growers aiming to satisfy consumer preferences. This blog presents a comprehensive analysis of the current market trends and the overall status of the greenhouse industry.

According to a market analysis report by Mordor Intelligence, the global greenhouse market, a key segment of the industrial greenhouse industry, was valued at USD 23.94 billion in 2020. It is forecasted to reach USD 43.67 billion by 2026, exhibiting a Compound Annual Growth Rate (CAGR) of 9.3% during the forecast period (2021-2026). Additionally, the report highlights that the total greenhouse acreage worldwide stands at approximately 4.9 million acres, underlining the industry’s expansive scale and the benefits of greenhouse farming.

In terms of industry trends, tomatoes, cucumbers, and peppers are identified as the most commonly cultivated crops in greenhouses across the globe. The greenhouse farming industry also sees a significant production of other crops such as lettuce, herbs, strawberries, and various flowers, including roses and gerberas, with the selection of crops varying by region. This variation is influenced by several factors, including climate, market demand, and local agricultural practices, which collectively determine the trends within the industrial greenhouse industry.

The choice of cover materials for greenhouses is another trend that reflects the industry’s adaptability and innovation. Materials range from polyethylene film, the most prevalent due to its cost-effectiveness, to more durable but expensive options like glass. Polycarbonate, known for its lightweight and insulative properties, emerges as a popular alternative, alongside other materials such as acrylic, ETFE, and fiberglass.

A 2021 study by Rabobank estimates that 92% of global greenhouse acreage utilizes polyethylene, highlighting the industry’s preference but also its readiness to adapt to various climatic and agricultural needs. The selection of these materials significantly influences the internal environment of greenhouses, affecting factors such as light, heat, and humidity, which are crucial for crop growth and yield. This aspect of the greenhouse market analysis demonstrates the industry’s focus on optimizing production through technological and material advancements, showcasing the benefits of greenhouse farming.

Greenhouses vs. traditional outdoor agriculture

There are several motivations for using greenhouses instead of traditional open-field agriculture, including:

- Year-round production: Greenhouses allow for year-round production of crops regardless of weather conditions or seasonal changes. This is especially important in regions with extreme weather patterns or limited growing seasons. The benefits of greenhouse farming include the ability to extend growing periods and enhance productivity.

- Controlled environment: Greenhouses provide a controlled environment where growers can regulate temperature, humidity, and light levels to optimize plant growth and reduce the risk of pests and diseases. Controlled environments in industrial greenhouses are also less susceptible to weather-related disruptions and the repercussions of climate change.

- Increased yields: With the ability to control growing conditions, greenhouses can produce higher yields per square foot than traditional field agriculture. This advantage is particularly significant in greenhouse farming, where high-value crops such as fruits, vegetables, and herbs are cultivated.

- Improved quality: Greenhouses provide a clean and protected environment that can improve the quality and appearance of crops, resulting in higher market value. The benefits of greenhouse farming are evident in the superior quality and marketability of the produce.

Efficient use of resources: Greenhouses can be designed to use resources such as water and fertilizer more efficiently than field agriculture, resulting in reduced waste and lower costs. Industrial greenhouses exemplify the efficient resource management that contributes to sustainable agricultural practices.

Greenhouses vs. indoor agriculture

Greenhouse cultivation and indoor cultivation using artificial lighting are both forms of controlled environment agriculture, but there are some key differences between the two approaches.

Greenhouse cultivation, a key aspect of greenhouse farming, involves growing crops in a covered structure that allows natural sunlight to penetrate while protecting the plants from the elements. The use of natural sunlight means that energy costs for lighting are low, and the environmental conditions inside the industrial greenhouse are generally more stable than outside.

However, the amount of sunlight can vary depending on the weather and time of year, and growers may need to supplement natural light with artificial lighting during low-light periods to maintain optimal growth conditions for crops. In addition, greenhouse cultivation is subject to seasonal fluctuations and can be affected by extreme weather events.

Indoor cultivation using artificial lighting involves growing crops in an enclosed environment using artificial light sources such as LED or high-pressure sodium (HPS) lamps. This approach allows growers to control all aspects of the environment, including temperature, humidity, and light intensity, which can lead to consistent yields and high-quality crops.

Indoor cultivation is not subject to seasonal fluctuations and can produce crops year-round, which can be a significant advantage for growers. However, the energy costs associated with artificial lighting can be high, and the initial investment in equipment can also be expensive.

Overall, greenhouse cultivation is a more cost-effective and energy-efficient option compared to indoor cultivation using artificial lighting, highlighting the benefits of greenhouse farming. However, indoor cultivation provides greater control over the environment and can produce crops year-round, making it a viable option for certain crops and growing situations. The choice between the two approaches will depend on factors such as the type of crop being grown, the location of the operation, and the goals of the grower.

Greenhouses trends: present and future

The future looks bright for greenhouse farming, as demand for fresh produce and sustainable agriculture practices continue to grow. Here are some trends and developments that are shaping the future of industrial greenhouse agriculture:

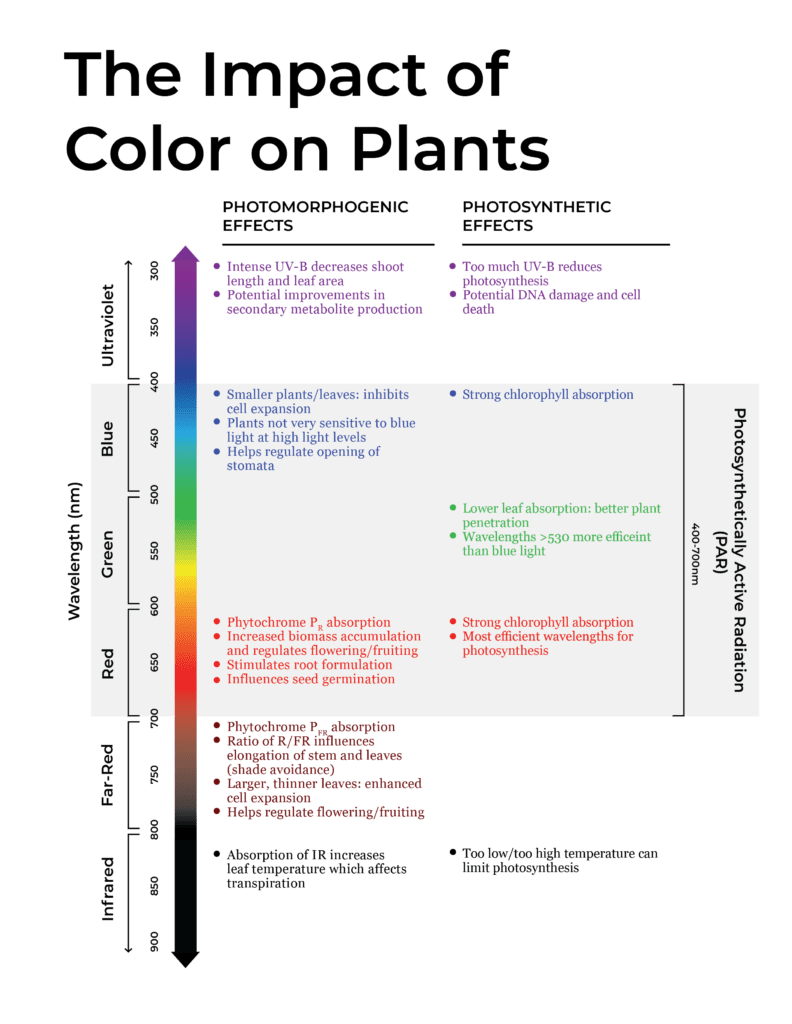

- Technology advancements: The use of technology in greenhouse farming is increasing, with innovations such as automation and robotics, spectral control by colored facades and coatings, automated climate control, precision irrigation, and data analytics. These technologies can help growers optimize plant growth and improve resource efficiency in industrial greenhouses.

- Sustainable practices: Greenhouse farming is becoming more sustainable, with a focus on reducing energy consumption, minimizing waste, and using organic growing methods. This trend is driven by consumer demand for environmentally friendly products and the need to address climate change, highlighting the benefits of greenhouse farming.

- Vertical farming: Vertical farming, which involves growing crops in stacked layers or vertically inclined surfaces, is gaining popularity as a way to maximize space and increase yields in industrial greenhouses. This approach is particularly useful in urban areas where land is limited. It can be done using artificial lighting or sunlight, showcasing the versatility and benefits of greenhouse farming.

- Shift to local food production: The pandemic has highlighted the importance of local food production, and greenhouse agriculture is well-suited to this trend. With the ability to produce fresh, high-quality produce year-round, greenhouses can play a key role in meeting the growing demand for locally grown food, further demonstrating the benefits of greenhouse farming.

Climate change as a driver for greenhouse cultivation

Climate change is expected to have a significant impact on food production worldwide, and controlled environment agriculture, including greenhouse farming, could play a critical role in ensuring food security in the face of changing climate conditions.

Here are some of the ways that climate change is expected to impact the need for controlled environment food production in greenhouses:

- Extreme weather events: Climate change is expected to increase the frequency and severity of extreme weather events such as droughts, floods, and storms. Greenhouses provide a controlled environment that can help protect crops from the impacts of these events and ensure consistent yields, highlighting one of the benefits of greenhouse farming.

- Heat stress: As temperatures rise, many crops may experience heat stress, which can reduce yields and quality. Greenhouses provide a controlled environment where temperature and humidity can be regulated to optimize plant growth and reduce the risk of heat stress, showcasing another key benefit of this industrial greenhouse approach.

- Water scarcity: Climate change is expected to exacerbate water scarcity in many regions, making it more difficult to grow crops in the field. Greenhouses can be designed to use water more efficiently, reducing waste and ensuring consistent yields even in water-stressed areas.

- Pests and diseases: Changes in temperature and precipitation patterns can also affect pest and disease pressure in crops, leading to increased risks for farmers. Greenhouses provide a clean and protected environment that can reduce the risk of pest and disease outbreaks and ensure high-quality, healthy crops.

Overall, the impacts of climate change are expected to increase the need for controlled environment food production in greenhouses, as they offer a more reliable and consistent way to produce food in the face of changing climate conditions. This underlines the benefits of greenhouse farming in an era of environmental uncertainty.

Conclusion

In conclusion, the global greenhouse industry, a significant segment of the agricultural market, is experiencing rapid growth, underscored by the rising demand for fresh produce. This trend is reflective of the broader market analysis within the greenhouse sector, which identifies greenhouses as offering many advantages over traditional outdoor agriculture.

These benefits of greenhouse farming include year-round production, a controlled environment, increased yields, improved quality, and efficient use of resources, all of which are key factors driving the greenhouse market. While greenhouse cultivation and indoor cultivation using artificial lighting are both forms of controlled environment agriculture, the former is generally more cost-effective and energy-efficient, an important consideration in industrial greenhouse industry trends.

The future of greenhouse farming looks bright, buoyed by advancements in technology, sustainable practices, vertical farming, and a shift towards local food production. These developments are shaping the industry and align with the trends identified in greenhouse market analysis. As the world population continues to grow, the greenhouse industry, with its innovative approaches to cultivation and production, will play a crucial role in meeting the increasing demand for fresh, healthy, and sustainably produced food.

The ongoing analysis of greenhouse market trends and industry insights will undoubtedly continue to provide valuable guidance for stakeholders within this vibrant sector.

Dr. Damon Hebert

Dr. Damon Hebert serves as Director of Agriculture Research for UbiQD, Inc., with a background in solar materials and controlled environment cannabis cultivation. He is an advocate for the use of advanced materials to further the industry’s push towards sustainable farming practices. He can be reached at [email protected].

Share:

Connect With Us

Company

Resources

Hunter McDaniel, PhD

Founder & CEO

Hunter earned a Ph.D. in Materials Science and Engineering at the University of Illinois at Urbana-Champaign, before joining Los Alamos National Laboratory in the Chemistry Division. Ultimately the value proposition of UbiGro is about boosting crop yields and quality without the cost or energy impact of lighting. Hunter has more than fifty publications and patents, and more than 2000 total citations, h-index: 20. Hunter fundamentally believes that novel materials underpin every significant technology advancement, and he is focused on leveraging new materials to have a lasting and sustainable impact.

Damon Hebert, PhD

Director of Agriculture

Damon brings a wide range of experience in agriculture, materials science, spectroscopy, and small business. During his time in Prof. Angus Rockett’s research group at The University of Illinois at Urbana-Champaign (UIUC), Hebert authored a doctoral thesis and multiple papers on the materials science of CIGS semiconductor materials, which is closely related to the materials developed at UbiQD. He also served as a consultant to Nanosolar, a CIGS nanocrystal solar cell manufacturing company. Hebert has industry experience having co-founded Dr. Jolly’s, a leading cultivation and distribution operation in Bend, OR.

Tania Lafaille

Sales Representative

Tania is a UbiGro Sales Representative, with over 7 years of experience in product sales (specifically berries and avocados) covering all of North America and parts of South America. While in agriculture, Tania has cultivated strong relationships with growers and distributors, granting her a unique insight into both perspectives. That understanding, paired with her fierce dedication to results, drives her fun and fiery commitment to her craft. Tania is based in Gilroy, CA.

Tyler Veyna

Sales Representative

Tyler brings 15 years of experience in Greenhouse production and facility management of a wide range of crops in multiple states to the UbiGro team. Based in Salinas, California. “Being a fourth-generation farmer, I look to improve and empower the grower, and with UbiGro, we can do just that.”

Jim Gideon

Sales Manager

Jim Gideon is an UbiGro Sales Manager, with over 25 years of greenhouse industry sales experience covering all of North America. Previously Jim has worked for Green Tek, Plazit-Polygal, Texel, Cherry Creek, and Nexus. He is based in Montgomery, AL, and Jim believes that “light is everything to the grower.”

Eric Moody

Director of Sales

Eric Moody is UbiQD’s Director of UbiGro Sales. Eric has more than 6 years of experience in horticulture lighting industry, building relationships with greenhouse growers of all sizes and crops on optimal lighting for their growing operation, and most recently managed a North American sales team for PL Light Systems. Overall, Eric has been in sales leadership positions for more than 13 years. Eric brings with him a great understanding of the market and available technologies for growers, greenhouse facilities, and sales leadership. Reach Eric by phone at 541-490-6421 or by email at [email protected].

Mike Burrows, PhD

Dr. Michael Burrows is UbiQd’s Vice President of Business Development. His educational background includes a Materials Science doctorate from the University of Delaware and an MBA from Duke University Fuqua School of Business. His career has specialized in the commercialization of novel electronic materials in venture-run programs for different industries including solar, biosensors, and the automotive industry. In both start-up and corporate environments, he has extensive experience in global market development, foraging supply chain partnerships, productization, and brand building. He is currently leading UbiQD’s partnership efforts in luminescent greenhouse technology, smart windows, and security ventures.

Matt Bergern, PhD

Cheif Product Officer

As Chief Product Officer at UbiQD, Dr. Matt Bergren leads the company’s product development efforts, sales, and product manufacturing, including the company’s first commercial agriculture product, UbiGro. He plays a critical role in continuing the company’s path of technology development and vision of powering product innovations in agriculture, clean energy, and security.

He serves as the principal investigator for UbiQD’s contract with NASA, focused on tailoring the solar spectrum for enhanced crop production for space missions. Dr. Bergren’s leadership experience includes serving on the board of directors for the New Mexico Energy Manufacturing Institute, focused on job creation in New Mexico’s energy, and related manufacturing community.