+20% Boost in Tomatoes

AT A GLANCE

- Results

- Crop

- Farm

- Location

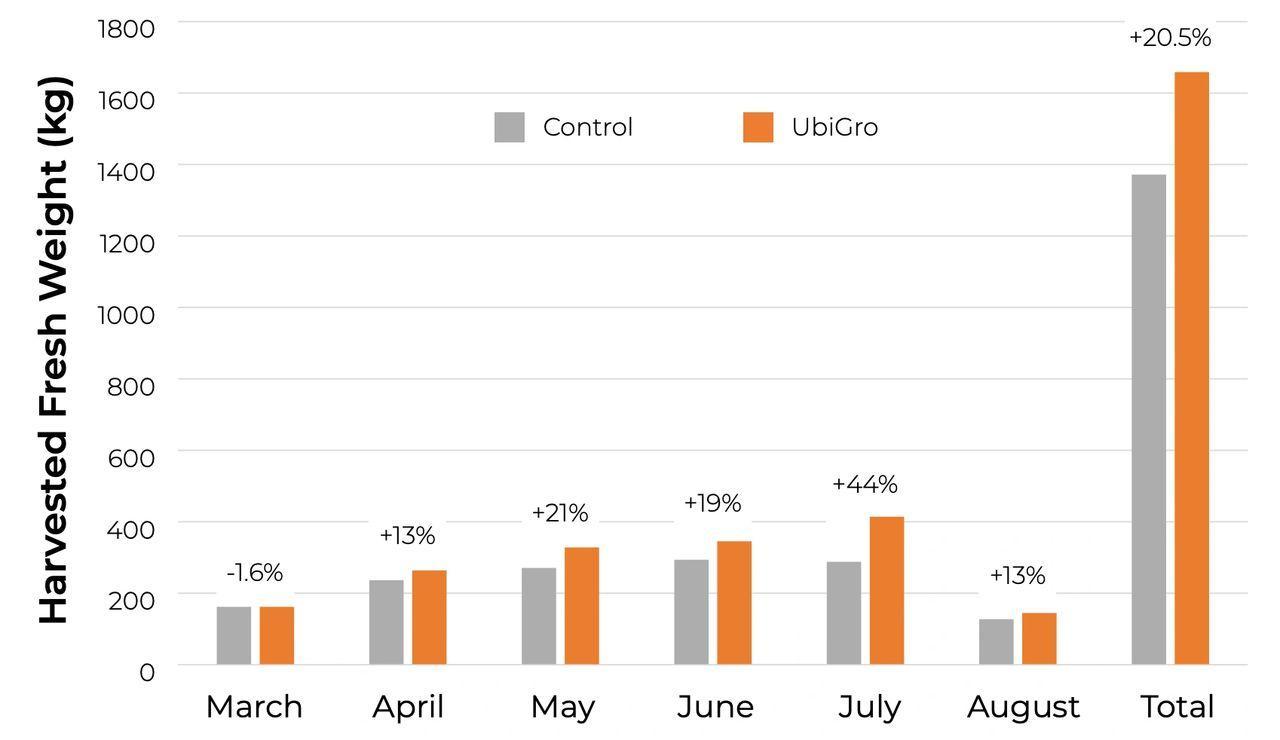

This study resulted in a +20.5% overall increase in fresh weight harvested under the UbiGro films relative to the control.

252 Hydroponic Beefsteak Tomatoes.

Alcalde, NM, USA.

ABOUT THE PROJECT

Alcalde, NM, USA | UbiGro films were installed and tested in a hydroponic greenhouse located at Growing Opportunities Farm in Alcalde, NM. In this five-month plant trial, two sections of UbiGro films were suspended over a row of 126 beefsteak tomato plants. The tomato production under these films was compared to a control row located in the same greenhouse that was only exposed to un-modified sunlight. There were three rows of tomatoes in between the two test rows, which served as barrier rows, ensuring the light conditions for the film and control row were distinct. The 30’x90’ greenhouse had a double polyethylene cover that was whitewashed to lower light intensity during the summer.

Beefsteak Tomato Production

THE UBIGRO FILM ENHANCED TOMATO PRODUCTION IN 4 OF 5 MONTHS OF THE TRIAL, WITH A TOTAL YIELD ENHANCEMENT OF +20.5%.

The data for this tomato plant trial is shown on above, where a yield enhancement was consistently observed throughout the duration of the trial. This resulted in a +20.5% overall increase in fresh weight harvested under the UbiGro films relative to the control. The benefit was most pronounced in high-light level months, June and July. There were no observed differences in color, flavor, or overall quality of the fruit harvested from the two separate rows of tomatoes.

Did you know? UbiGro films are designed to maintain their optical performance for 4 years and have an expected usable life of 6 years.

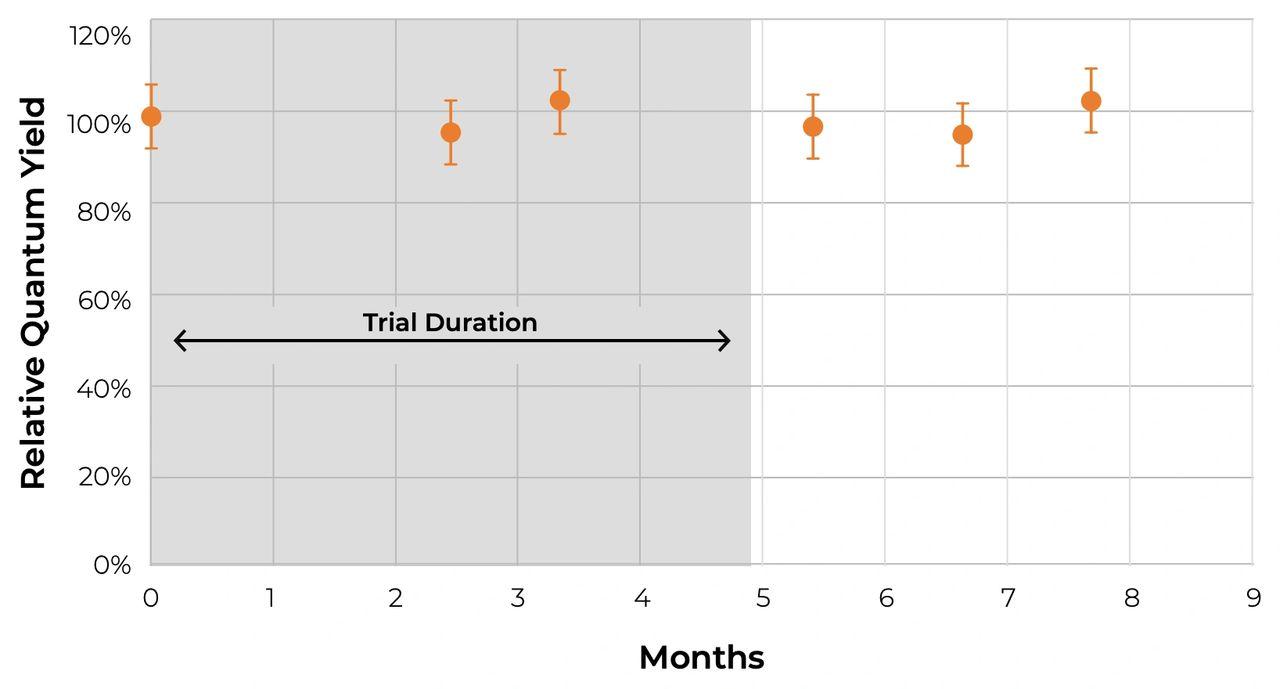

Films were tested for stability regularly throughout the plant trial and the relative luminescent quantum yield, or photon conversion efficiency, was compared (above). The quantum yield of the film correlates with the brightness of the emission, and therefore indicates the performance of the film over time. Over the course of the five-month summer trial, the UbiGro films showed no degradation in quantum yield, indicating no change in the optical properties of the film. The films have remained installed in the greenhouse for an additional 77 days and the film has maintained its original optical performance.

UbiGro: Stability in Greenhouse

ECONOMICS

CONCLUSION

In order to quantify the value of the increase in revenue, we must calculate the increased profit. There are variable costs associated with producing and selling this extra produce, including harvesting, packaging, and transportation. However, fixed costs are not increased with the additional yield. These costs include real estate (rent/mortgage), heating/cooling, electricity, marketing, and labor (such as cleaning, seeding, vegetative labor, etc.). Given that the gross margin on the baseline production of beefsteak tomatoes at Growing Opportunities farm is 68% (32% COGS), we can estimate an 84% gross margin on any extra production (16% COGS) realized as a result of the superior UbiGro spectrum.

In this example, that translates to +$12,807 additional profit per year from this greenhouse. Over the projected 4-yr life of the installed UbiGro film, the farm would take in over +$51,000 in extra profit from this greenhouse alone.

Share:

Connect With Us

Company

Resources

Hunter McDaniel, PhD

Founder & CEO

Hunter earned a Ph.D. in Materials Science and Engineering at the University of Illinois at Urbana-Champaign, before joining Los Alamos National Laboratory in the Chemistry Division. Ultimately the value proposition of UbiGro is about boosting crop yields and quality without the cost or energy impact of lighting. Hunter has more than fifty publications and patents, and more than 2000 total citations, h-index: 20. Hunter fundamentally believes that novel materials underpin every significant technology advancement, and he is focused on leveraging new materials to have a lasting and sustainable impact.

Damon Hebert, PhD

Director of Agriculture

Damon brings a wide range of experience in agriculture, materials science, spectroscopy, and small business. During his time in Prof. Angus Rockett’s research group at The University of Illinois at Urbana-Champaign (UIUC), Hebert authored a doctoral thesis and multiple papers on the materials science of CIGS semiconductor materials, which is closely related to the materials developed at UbiQD. He also served as a consultant to Nanosolar, a CIGS nanocrystal solar cell manufacturing company. Hebert has industry experience having co-founded Dr. Jolly’s, a leading cultivation and distribution operation in Bend, OR.

Tania Lafaille

Sales Representative

Tania is a UbiGro Sales Representative, with over 7 years of experience in product sales (specifically berries and avocados) covering all of North America and parts of South America. While in agriculture, Tania has cultivated strong relationships with growers and distributors, granting her a unique insight into both perspectives. That understanding, paired with her fierce dedication to results, drives her fun and fiery commitment to her craft. Tania is based in Gilroy, CA.

Tyler Veyna

Sales Representative

Tyler brings 15 years of experience in Greenhouse production and facility management of a wide range of crops in multiple states to the UbiGro team. Based in Salinas, California. “Being a fourth-generation farmer, I look to improve and empower the grower, and with UbiGro, we can do just that.”

Jim Gideon

Sales Manager

Jim Gideon is an UbiGro Sales Manager, with over 25 years of greenhouse industry sales experience covering all of North America. Previously Jim has worked for Green Tek, Plazit-Polygal, Texel, Cherry Creek, and Nexus. He is based in Montgomery, AL, and Jim believes that “light is everything to the grower.”

Eric Moody

Director of Sales

Eric Moody is UbiQD’s Director of UbiGro Sales. Eric has more than 6 years of experience in horticulture lighting industry, building relationships with greenhouse growers of all sizes and crops on optimal lighting for their growing operation, and most recently managed a North American sales team for PL Light Systems. Overall, Eric has been in sales leadership positions for more than 13 years. Eric brings with him a great understanding of the market and available technologies for growers, greenhouse facilities, and sales leadership. Reach Eric by phone at 541-490-6421 or by email at [email protected].

Mike Burrows, PhD

Dr. Michael Burrows is UbiQd’s Vice President of Business Development. His educational background includes a Materials Science doctorate from the University of Delaware and an MBA from Duke University Fuqua School of Business. His career has specialized in the commercialization of novel electronic materials in venture-run programs for different industries including solar, biosensors, and the automotive industry. In both start-up and corporate environments, he has extensive experience in global market development, foraging supply chain partnerships, productization, and brand building. He is currently leading UbiQD’s partnership efforts in luminescent greenhouse technology, smart windows, and security ventures.

Matt Bergern, PhD

Cheif Product Officer

As Chief Product Officer at UbiQD, Dr. Matt Bergren leads the company’s product development efforts, sales, and product manufacturing, including the company’s first commercial agriculture product, UbiGro. He plays a critical role in continuing the company’s path of technology development and vision of powering product innovations in agriculture, clean energy, and security.

He serves as the principal investigator for UbiQD’s contract with NASA, focused on tailoring the solar spectrum for enhanced crop production for space missions. Dr. Bergren’s leadership experience includes serving on the board of directors for the New Mexico Energy Manufacturing Institute, focused on job creation in New Mexico’s energy, and related manufacturing community.