Light Manipulation for Ornamental Crop Production

Have you ever heard of an ornamental kale or pepper plant? Rather than being grown for consumption, these ornamentals are cherished for their aesthetic appeal: showcasing leaves, fruits, and flowers of interesting colors, shapes, and aromas, thus contributing significantly to ornamental crop production systems (Figure 1).

According to the most recent USDA census, the U.S. ornamental production industry, which is a key segment of crop growth strategies, is valued at $6.2 billion per year. This industry encompasses over 17,000 growers who utilize glass or other controlled environments for their crops, demonstrating the importance of advanced production systems in enhancing the aesthetic and economic value of ornamental plants (USDA NASS, 2020).

These controlled environment growers adeptly manipulate light to alter plant shape, increase cutting quantity, and, in the case of flowering ornamentals, control flowering time. Such light manipulation practices are essential for crop scheduling and optimization in ornamental crop production systems (Runkle and Heins, 2006). Greenhouse lighting plays a crucial role in these controlled environments, helping growers manage plant growth and flowering cycles effectively.

Greenhouse growers employ various products to manipulate light, including shade/blackout cloths, exterior applied greenhouse coatings, and supplemental lighting. Additionally, understanding the plant light spectrum allows growers to fine-tune lighting conditions to optimize growth, enhance coloration, and improve the overall quality of ornamental crops. These techniques are pivotal in enhancing crop growth, ensuring the year-round production and supply of high-quality ornamental plants.

Figure 1. Bolivian rainbow pepper, medusa pepper, and ornamental kale showing eye-catching fruits and leaves.

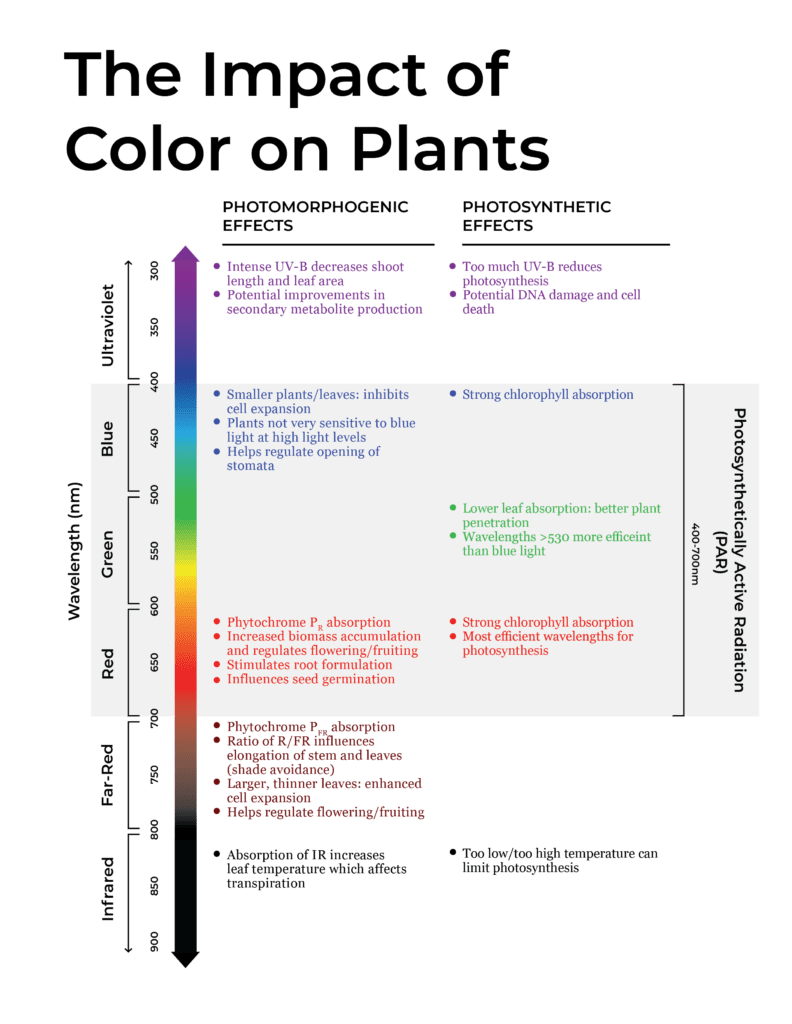

To understand the applications of these different products, two adjustable characteristics of light are important to know: light quality and light quantity. Light manipulation plays a crucial role in optimizing these characteristics for plant growth. Light quality pertains to the spectral wavelength composition of the light source; for example, sunlight quality at Earth’s surface is approximately 43% photosynthetically active radiation (PAR) (400-700nm) and 4% ultraviolet (UV) (300-400 nm) (National Renewable Energy Laboratory, n.d.).

PAR and UV light, as well as far-red (700-750 nm), contribute to plant growth and development and are called biologically active radiation (Zhen et Figure 1. Bolivian rainbow pepper, medusa pepper, and ornamental kale showing eye-catching fruits and leaves.al., 2021). The plant light spectrum, including these wavelengths, directly influences plant health and productivity. PAR, however, is the most critical to plant growth because it contributes directly to photosynthesis.

Light quantity is the amount of PAR light received, expressed as daily light integral (DLI). Two variables contribute to DLI. One is instantaneous light intensity, or the number of PAR photons received during one second in a given area, expressed as photosynthetic photon flux density (PPFD).

Second is the duration of light received during a day, called photoperiod. Photoperiod is crucial for plant development, most notably inducing flowers in many crops. Commercial growers primarily manipulate light quantity; however, other light characteristics (including quality) change. Greenhouse lighting systems allow growers to fine-tune both light quantity and quality to maximize plant performance.

Decreasing PPFD – Shade Cloths

One reason ornamental growers reduce PPFD is to grow plants that naturally thrive in shadier environments, such as coleus, begonia, and impatiens. Light manipulation techniques, such as using shade cloths, called shade nets or screens, are commonly used to decrease PPFD. They contain materials that reflect or absorb light, resulting in more diffuse light that can penetrate deeper into the crop canopy (Shahak, 2006).

This diffuse light provides side-lighting to hanging basket plants (Figure 2), which had total sales of $67.2 million in 2020 (USDA, 2020). Greenhouse lighting plays a crucial role in ensuring hanging baskets receive even weight dispersion on all sides to avoid tipping, including evenly dispersed lighting to obtain the desired plant structure with light diffusion.

One of the most popular hanging basket ferns grown in controlled environments is the Boston fern. Seltsam and Owen (2022) used shade cloths to apply five different levels of DLI to identify an optimal range to grow the species. A DLI range of 10-12 mol m-2d-1 Figure 2.

Production greenhouses are growing hanging baskets above rows to maximize their space use efficiency. They maximized the frond number in 7 of 11 cultivars. Based on height and diameter, plant compaction was also optimized for ‘Compacta’ and ‘Super’ within this range. Plant light spectrum adjustments can further enhance plant growth, ensuring optimal development under controlled lighting conditions.

Figure 2. Production greenhouses growing hanging baskets above rows to maximize their space use efficiency.

One of the most popular hanging basket ferns grown in controlled environments is the Boston fern. Seltsam and Owen (2022) used shade cloths to apply five different levels of DLI to identify an optimal range to grow the species. A DLI range of 10-12 mol m2 d1 Maximized frond number in 7 of 11 cultivars. Based on height and diameter, plant compaction was also optimized for ‘Compacta’ and ‘Super’ within this range.

Shade cloths improve plant structure not only by decreasing PPFD and diffusing light but also by decreasing the amount of heat a crop receives, which impacts stem elongation and leaf expansion (Erwin and Heins, 1995; Dale, 1964, 1965; Milthorpe, 1959). As a result, shade cloths provide ideal conditions for crops that prefer cooler temperatures, such as marigolds, chrysanthemums, and pansies. Austerman et al. (2023) grew pansies for six weeks under red, black, pearl, and aluminized shade cloths to see which color cloth improved plant compaction.

Pearl-colored shade cloths decreased the height the plant had to reach to flower and grow true leaves, indicating a more compact growth habit, which makes damage during shipment less likely. These examples demonstrate the usefulness of shade cloths to improve plant growth uniformity and compaction by providing more diffuse light and decreasing heat the plants receive.

Decreasing Photoperiod – Blackout Cloths

Another option to decrease DLI is to decrease photoperiod. Growers primarily decrease photoperiod to induce flowering in short-day plants (SDPs), which flower only when the night length is above a critical minimum (Yang, 2022).

Growers can use blackout cloths to simulate short days. Light manipulation through blackout cloths helps regulate flowering cycles effectively. Blackout cloths have synthetic black fibers with reflective outer surfaces that prevent sunlight from reaching the crop. It is common to see them installed as curtains operating autonomously inside greenhouse lighting systems (Figure 3).

Ornamental SDPs of economic importance include chrysanthemum, Christmas cactus, and poinsettia. Controlling the flowering of these seasonal specialty crops is necessary to produce marketable plants for sale just before a particular holiday.

While blackout cloths can induce flowering in SDPs, the next product discussed, supplemental lighting, can be used to delay SDP flowering using night interruption lighting (NIL). NIL involves turning on artificial lights in Figure 3. Blackout clothes are ready to be deployed above chrysanthemums—the middle of the night leads plants to perceive the longest, unbroken darkness period as shorter. The plant light spectrum plays a crucial role in influencing plant responses under NIL strategies.

Figure 3. Blackout cloths are ready to be deployed.

Increasing DLI – Supplemental lighting

Supplemental lighting increases PPFD and extends photoperiod, so the crop receives more photons to drive photosynthesis and increase growth. Light manipulation plays a key role in optimizing greenhouse lighting, ensuring plants receive the ideal intensity and duration of light exposure. Traditional supplemental lighting includes metal-halide (MH) lamps, high-pressure sodium (HPS) lamps (Figure 4), and light-emitting diodes (LEDs) (Figure 5).

LEDs are the newest form of supplemental lighting and have improved features compared to MH and HPS, including higher energy use efficiency, longer working life, and tunable light output (Kim et al., 2004). More and more greenhouses are adopting LEDs due to their energy efficiency and color-tuning properties, which help optimize the plant light spectrum for enhanced growth and productivity.

Figure 4. Supplemental HPS lighting in Greenhouse.

The light quality of LEDs can be customized, which allows for the application of specific wavelengths to a crop. Light manipulation plays a crucial role in optimizing plant growth by adjusting spectral outputs. In a study by Collado and Hernández (2022), geranium ‘Maverick Red’ and petunia ‘Dreams Midnight’ were grown in greenhouse lighting conditions under supplemental red LEDs (670 nm) or HPS lamps. Compared to the HPS light quality, the red LEDs doubled the red light PPFD, increasing the red:far-red light ratio tenfold.

When using the same DLI, the morphology of the geraniums and petunias was more compact under LEDs compared to HPS lamps. Petunia also showed increased chlorophyll and anthocyanin concentrations, contributing to leaf color and ornamental value (Gazula et al., 2007). Figure 5.

LEDs in controlled environments. (Figure 4). Supplemental HPS lighting over orchids. Additionally, the study included a paclobutrazol (PBZ) application to compare plant compactness resulting from light manipulation to that from PBZ.

PBZ is a commonly used ornamental plant growth regulator (PGR) that increases plant compaction but is highly toxic to aquatic life (Syngenta, 2021). The compactness of petunia ‘Dreams Midnight’ was significantly greater under LED treatment than HPS, and the PBZ application did not intensify this effect. These results suggest that plant light spectrum adjustment through light manipulation without PGR compacts petunias.

Figure 5. LEDs in controlled environments.

Another benefit of increased red light is that mother plants can produce many cuttings. In Kobori et al. (2022), researchers grew two cultivars of impatiens under supplemental LED lights supplying 150 μmol m-2s-1 of various red:blue light ratios for 12 hours daily. This study highlights the role of light manipulation in optimizing plant growth. Two hundred two days after transplant, the treatment receiving the most significant proportion of red:blue light had produced 35% more cuttings than the control, which received no supplemental light.

The response differed between cultivars, suspected to result partially from higher leaf anthocyanin concentration in ‘Sunpatiens Compact Royal Magenta’ than ‘Sunpatiens Compact White.’ This variation demonstrates how the plant light spectrum influences plant characteristics. Responding to a question posed by Currey and Lopez (2013), whether the presence of leaf pigments in mother plants affects cutting quality. Additionally, greenhouse lighting plays a crucial role in ensuring optimal light conditions for plant development.

Passive Luminescent Greenhouse Layers

Luminescent layers allow for spectral modification like LEDs, but unlike LEDs, they do not require electricity. They convert portions of solar energy from less to more photosynthetically efficient wavelengths (UV and blue [200-500 nm] to red [600-700 nm]). This process plays a crucial role in light manipulation and greenhouse lighting, optimizing plant growth without additional energy consumption.

Unlike cloths, the energy is transferred to a different wavelength instead of filtering out, resulting in greater PAR intensities and crop yields. While the documentation of benefits of luminescent layers on edible crop growth exists, benefits to ornamental crops do not; however, fresh-cut flowers that prefer high light intensities, such as gladiolus and chrysanthemum, could benefit from advancements in plant light spectrum optimization.

Conclusion

Luminescent greenhouse layers, pivotal in light manipulation for ornamental crop production systems, utilize organic dyes and inorganic nanomaterials, including quantum dots, to optimize crop growth. Unlike dyes, quantum dots excel in converting solar energy more efficiently and exhibit greater stability under sunlight, making them superior for enhancing crop growth in ornamental crop production systems.

Under UbiGro, a quantum dot-based luminescent film (Figure 6), plants receive 10% more red light (600-700 nm) and 4% more far-red (700-750 nm) than sunlight. This alteration in plant light spectrum, crucial for light manipulation in crop growth, results in a 9.5% increase in the ratio of red:far-red and a 43% increase in red:blue light, significantly benefiting ornamental crop production systems and greenhouse lighting strategies.

Increasing the proportion of red light prevents shade avoidance syndrome, leading to more desirable ornamental plant growth (Keuskamp, 2010); examples of these effects were more compact geraniums and petunias in Collado and Hernández (2022). These outcomes, demonstrating the effectiveness of light manipulation in ornamental crop production systems, also include additional characteristics improved by increased red light, such as a more vibrant leaf color and increased cuttings (Collado and Hernández, 2022; Kobori et al., 2022), further underscoring the benefits of tailored plant light spectrum for crop growth.

Furthermore, UbiGro provides 5% more green light (500-600 nm) than sunlight. Green light, akin to diffuse light in its effects on plant growth, penetrates deep into plant canopies, enhancing radiation use efficiency and, consequently, growth (Tubiello et al., 1997). These greenhouse lighting adjustments offered by luminescent films are invaluable for modifying plant light spectrum in ornamental crop production systems, demonstrating the critical role of light manipulation in optimizing crop growth conditions.

Jeff Bates

Jeff Bates is Plant Biologist at UbiQD, Inc. With professional experience in both crop research and production, he has grown edible, ornamental, and medicinal crops using soilless cultivation methods in various controlled environment settings. These experiences have led him to believe that advancing controlled environment technologies is critical to supporting future generations.

Share:

Austerman, P., Dunn, B. L., Singh, H., Fontanier, C., & Stanphill, S. (2023). Height Control of Greenhouse-grown Pansy Using Colored Shade Nets. HortTechnology, 33(1), 36-43.

Ball RedBook 2012. Light. In: Ball RedBook, 18th ed., C. Beytes (ed.), Ball Publishing, Chicago IL.

Britton, C. M., & Dodd, J. D. (1976). Relationships of photosynthetically active radiation and shortwave irradiance. Agricultural Meteorology, 17(1), 1-7.

Collado, C. E., & Hernández, R. (2022). Effects of light intensity, spectral composition, and paclobutrazol on the morphology, physiology, and growth of petunia, geranium, pansy, and dianthus ornamental transplants. Journal of Plant Growth Regulation, 1-18.

Currey, C. J., & Lopez, R. G. (2013). Cuttings of Impatiens, Pelargonium, and Petunia propagated under light-emitting diodes and high-pressure sodium lamps have comparable growth, morphology, gas exchange, and post-transplant performance. HortScience, 48(4), 428-434.

Dale, J. E. (1965). Leaf growth in Phaseolus vulgaris: 2. Temperature effects and the light factor. Annals of Botany, 29(2), 293-308.

Dale, J. E. (1964). Some effects of alternating temperature on the growth of French bean plants. Annals of Botany, 28(1), 127-135.

Erwin, J. E., & Heins, R. D. (1995). Thermomorphogenic responses in stem and leaf development. HortScience, 30(5), 940-949.

Gazula, A., Kleinhenz, M. D., Scheerens, J. C., & Ling, P. P. (2007). Anthocyanin levels in nine lettuce (Lactuca sativa) cultivars: Influence of planting date and relations among analytic, instrumented, and visual assessments of color. HortScience, 42(2), 232-238.

Hebert, D., Boonekamp, J., Parrish, C. H., Ramasamy, K., Makarov, N. S., Castañeda, C., … & Bergren, M. R. (2022). Luminescent quantum dot films improve light use efficiency and crop quality in greenhouse horticulture. Frontiers in Chemistry, 10, 988227.

Keuskamp, D. H., Sasidharan, R., & Pierik, R. (2010). Physiological regulation and functional significance of shade avoidance responses to neighbors. Plant signaling & behavior, 5(6), 655-662.

Kim, S. J., Hahn, E. J., Heo, J. W., & Paek, K. Y. (2004). Effects of LEDs on net photosynthetic rate, growth and leaf stomata of chrysanthemum plantlets in vitro. Scientia Horticulturae, 101(1-2), 143-151.

Kobori, M. M. R. G., da Costa Mello, S., de Freitas, I. S., Silveira, F. F., Alves, M. C., & Azevedo, R. A. (2022). Supplemental light with different blue and red ratios in the physiology, yield and quality of Impatiens. Scientia Horticulturae, 306, 111424.

Milthorpe, F. L. (1959). Studies on the expansion of the leaf surface: I. The influence of temperature. Journal of Experimental Botany, 10(2), 233-249.

National Renewable Energy Laboratory. (n.d.). Solar Spectra. NREL.gov. https://www.nrel.gov/grid/solar-resource/spectra.html

Reynolds, K. J., De Kock, J. P., Tarassenko, L., & Moyle, J. T. B. (1991). Temperature dependence of LED and its theoretical effect on pulse oximetry. British journal of anaesthesia, 67(5), 638-643.

Riga, P. (2012). Avoiding the use of plant growth regulator in geranium production by application of a cyclic deficit irrigation strategy. Journal of Applied Horticulture, 14(1).

Runkle, E. S., & Heins, R. D. (2005, June). Manipulating the light environment to control flowering and morphogenesis of herbaceous plants. In V International Symposium on Artificial Lighting in Horticulture 711 (pp. 51-60).

Seltsam, L., & Owen, W. G. (2022). Photosynthetic Daily Light Integral Influences Growth, Morphology, Physiology, and Quality of Swordfern Cultivars. HortScience, 57(12), 1564-1571.

Shahak, Y., Gal, E., Offir, Y., & Ben-Yakir, D. (2008, October). Photoselective shade netting integrated with greenhouse technologies for improved performance of vegetable and ornamental crops. In International Workshop on Greenhouse Environmental Control and Crop Production in Semi-Arid Regions 797 (pp. 75-80).

Syngenta. (2021). Syngenta BONZI [Safety data sheet]. (S175984119). https://assets.syngenta.ca/pdf/ca/msds/Bonzi_25453_en_SDS.pdf

Tubiello, F., Volk, T., & Bugbee, B. (1997). Diffuse light and wheat radiation-use efficiency in a controlled environment. Life Support & Biosphere Science, 4(1-2), 77-85.

U.S. Department of Agriculture, National Agricultural Statistics Service 2020 2019 Census of Horticultural Specialties.

https://www.nass.usda.gov/Publications/AgCensus/2017/Online_Resources/Census_of_Horticulture_Specialties/HORTIC.pdf.

Warner, R. M., & Erwin, J. E. (2003). Effect of photoperiod and daily light integral on flowering offive Hibiscus sp. Scientia Horticulturae, 97(3-4), 341-351.

Whitman, C., Padhye, S., & Runkle, E. S. (2022). A high daily light integral can influence photoperiodic flowering responses in long day herbaceous ornamentals. Scientia Horticulturae, 295, 110897.

Yang, J., Song, J., & Jeong, B. R. (2022). The flowering of SDP chrysanthemum in response to intensity of supplemental or night-interruptional blue light is modulated by both photosynthetic carbon assimilation and photoreceptor-mediated regulation. Frontiers in Plant Science, 13.

Yang, J., Song, J., & Jeong, B. R. (2022). Low-intensity blue light supplemented during photoperiod in controlled environment induces flowering and antioxidant production in kalanchoe. Antioxidants, 11(5), 811.

Zhen, S., van Iersel, M., & Bugbee, B. (2021). Why far-red photons should be included in the definition of photosynthetic photons and the measurement of horticultural fixture efficacy. Frontiers in Plant Science, 1158.

Connect With Us

Company

Resources

Hunter McDaniel, PhD

Founder & CEO

Hunter earned a Ph.D. in Materials Science and Engineering at the University of Illinois at Urbana-Champaign, before joining Los Alamos National Laboratory in the Chemistry Division. Ultimately the value proposition of UbiGro is about boosting crop yields and quality without the cost or energy impact of lighting. Hunter has more than fifty publications and patents, and more than 2000 total citations, h-index: 20. Hunter fundamentally believes that novel materials underpin every significant technology advancement, and he is focused on leveraging new materials to have a lasting and sustainable impact.

Damon Hebert, PhD

Director of Agriculture

Damon brings a wide range of experience in agriculture, materials science, spectroscopy, and small business. During his time in Prof. Angus Rockett’s research group at The University of Illinois at Urbana-Champaign (UIUC), Hebert authored a doctoral thesis and multiple papers on the materials science of CIGS semiconductor materials, which is closely related to the materials developed at UbiQD. He also served as a consultant to Nanosolar, a CIGS nanocrystal solar cell manufacturing company. Hebert has industry experience having co-founded Dr. Jolly’s, a leading cultivation and distribution operation in Bend, OR.

Tania Lafaille

Sales Representative

Tania is a UbiGro Sales Representative, with over 7 years of experience in product sales (specifically berries and avocados) covering all of North America and parts of South America. While in agriculture, Tania has cultivated strong relationships with growers and distributors, granting her a unique insight into both perspectives. That understanding, paired with her fierce dedication to results, drives her fun and fiery commitment to her craft. Tania is based in Gilroy, CA.

Tyler Veyna

Sales Representative

Tyler brings 15 years of experience in Greenhouse production and facility management of a wide range of crops in multiple states to the UbiGro team. Based in Salinas, California. “Being a fourth-generation farmer, I look to improve and empower the grower, and with UbiGro, we can do just that.”

Jim Gideon

Sales Manager

Jim Gideon is an UbiGro Sales Manager, with over 25 years of greenhouse industry sales experience covering all of North America. Previously Jim has worked for Green Tek, Plazit-Polygal, Texel, Cherry Creek, and Nexus. He is based in Montgomery, AL, and Jim believes that “light is everything to the grower.”

Eric Moody

Director of Sales

Eric Moody is UbiQD’s Director of UbiGro Sales. Eric has more than 6 years of experience in horticulture lighting industry, building relationships with greenhouse growers of all sizes and crops on optimal lighting for their growing operation, and most recently managed a North American sales team for PL Light Systems. Overall, Eric has been in sales leadership positions for more than 13 years. Eric brings with him a great understanding of the market and available technologies for growers, greenhouse facilities, and sales leadership. Reach Eric by phone at 541-490-6421 or by email at [email protected].

Mike Burrows, PhD

Dr. Michael Burrows is UbiQd’s Vice President of Business Development. His educational background includes a Materials Science doctorate from the University of Delaware and an MBA from Duke University Fuqua School of Business. His career has specialized in the commercialization of novel electronic materials in venture-run programs for different industries including solar, biosensors, and the automotive industry. In both start-up and corporate environments, he has extensive experience in global market development, foraging supply chain partnerships, productization, and brand building. He is currently leading UbiQD’s partnership efforts in luminescent greenhouse technology, smart windows, and security ventures.

Matt Bergern, PhD

Cheif Product Officer

As Chief Product Officer at UbiQD, Dr. Matt Bergren leads the company’s product development efforts, sales, and product manufacturing, including the company’s first commercial agriculture product, UbiGro. He plays a critical role in continuing the company’s path of technology development and vision of powering product innovations in agriculture, clean energy, and security.

He serves as the principal investigator for UbiQD’s contract with NASA, focused on tailoring the solar spectrum for enhanced crop production for space missions. Dr. Bergren’s leadership experience includes serving on the board of directors for the New Mexico Energy Manufacturing Institute, focused on job creation in New Mexico’s energy, and related manufacturing community.