The Harsh Truth About LED Greenhouse Lighting

Sunlight is considered the overall best option for growing but in some areas of the world and certain times of the year there simply is not enough light or Daily Light Integral (DLI) for maximum growth so growers turn to supplemental lighting to fill in when DLI is low and in today’s market, the popular lighting systems for growers are LEDs, including high intensity LED lights. We know sunlight is superior to LED light for plant growth due to its natural and comprehensive spectrum of wavelengths, which plants have evolved to utilize efficiently over millions of years. Here we will take a look at several reasons why sunlight is often preferred over LED greenhouse lighting when available and how we may optimize this free light source while considering the benefits of supplemental light for plants.

Spectrum and Intensity Concerns

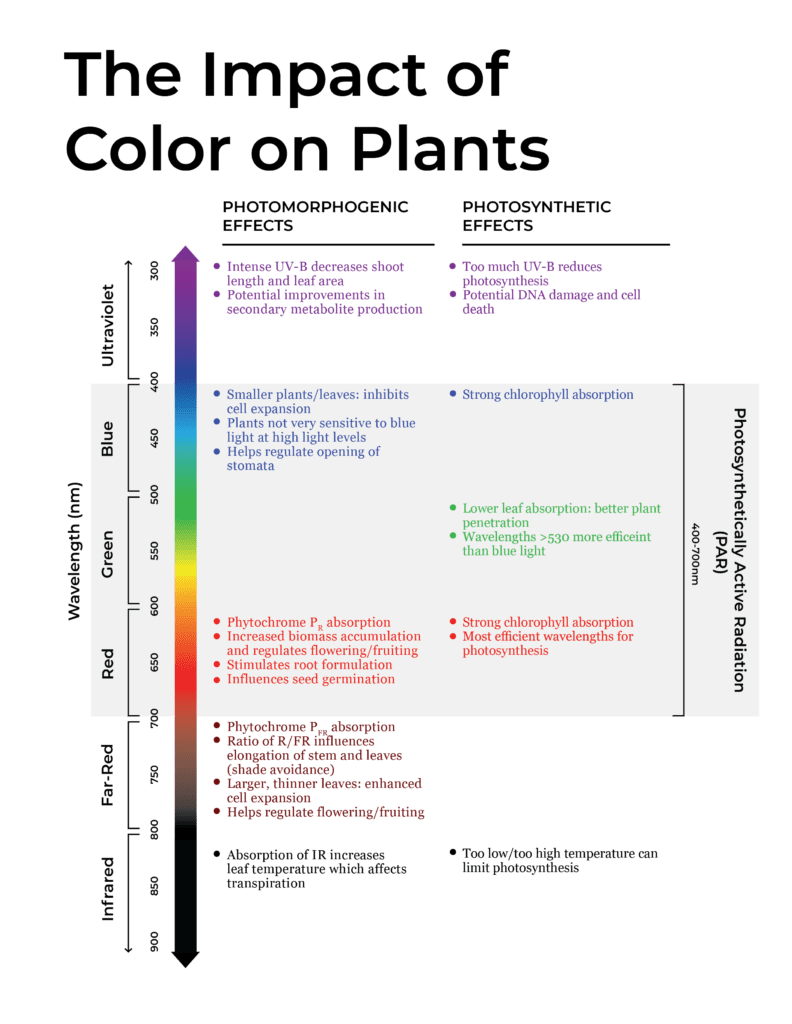

There are concerns about the spectrum and intensity of light that Light Emitting Diodes (LEDs) emit. LEDs emit a narrow spectrum of light, which can be problematic for certain applications. You can read examples of this in past blogs like “The Power of Redlight in Greenhouse Farming” and “The Green Light Myth.” For example, in indoor agriculture, plants require a specific combination of light wavelengths for optimal growth. LEDs, including LED greenhouse lighting and high intensity LED lights, may not provide the full spectrum of light that plants need, leading to suboptimal growth and development.

In addition to spectrum concerns, the intensity of LEDs can also be an issue. LEDs are known for their brightness, and this can be overwhelming in certain settings.

One common issue arises from exposing plants to excessive light intensity or light of the incorrect spectrum. This can lead to various problems such as heightened stress levels, leaf burn, or even stunted growth. Supplemental light for plants using the correct spectrum and intensity is crucial to avoid these issues.

Moreover, the quality of LEDs also plays a significant role in determining their impact on plant growth. Certain LEDs may lack certain wavelengths crucial for plant development or exhibit inconsistencies in light output, both of which can have adverse effects on overall plant health and productivity.

Light Intensity and Leaf Damage

One of the concerns related to LEDs, including led greenhouse lighting, is their potential to damage leaves. High-intensity LEDs, often used as supplemental light for plants, can  damage the leaves of plants. The intense light can cause photobleaching, which is the process of breaking down chlorophyll in the leaves. This can lead to the leaves turning yellow or white and eventually dying off, inhibiting photosynthesis and fruit production.

damage the leaves of plants. The intense light can cause photobleaching, which is the process of breaking down chlorophyll in the leaves. This can lead to the leaves turning yellow or white and eventually dying off, inhibiting photosynthesis and fruit production.

LEDs, especially high intensity LED lights, can inadvertently cause leaf burn when plants are subjected to excessive light intensity or prolonged exposure to light. Leaf burn occurs when the energy from the light is absorbed by the leaf tissues at a rate faster than they can dissipate or utilize it effectively. This excess energy can lead to overheating and damage to the leaf cells, resulting in visible symptoms such as browning, yellowing, or necrosis of the leaf edges or surfaces. This problem is an extremely common problem for growers with LED lighting systems.

Leaf burn not only compromises the appeal of plants but also impairs their ability to carry out essential physiological processes such as photosynthesis. Damaged leaves are less efficient at capturing light and converting it into energy, which can ultimately impact overall plant growth and yield. Furthermore, repeated or severe instances of leaf burn can weaken the plant’s defenses against pests and diseases, making it more susceptible to further damage.

LED Light Quality Compared to the Sun

While LEDs, such as LED greenhouse lighting and high intensity LED lights, can provide a bright and efficient source of light, they may not fully replicate the quality of sunlight. Sunlight has a broad spectrum of light source that includes all colors of the rainbow, whereas LEDs emit a narrower or limited spectrum. This difference in spectrum can have implications for certain applications.

Here are just a few things that sunlight can offer you whereas LEDs lack:

- Full Spectrum: Sunlight provides a full spectrum of wavelengths, including visible light, ultraviolet (UV), and infrared (IR) light. This broad spectrum ensures that plants receive all the wavelengths they need for various physiological processes, including photosynthesis, photomorphogenesis, and photoperiodism. While LEDs can be used to dial spectrum for controlling certain aspects of growth like plant morphology, it can also be lacking in certain spectrum that can affect fruit growth, quality, etc.

- Balanced Intensity: The intensity of sunlight varies throughout the day and is influenced by factors such as time of day, weather conditions, and geographic location. This balance of light intensity improves the diffusion of light into the canopy. Plants have evolved to adapt to these fluctuations in light intensity, which can positively influence their growth and development. LEDs, used as supplemental light for plants, tend to be a very directional light form. The emitted photons from diodes are not bouncing around like the photons from sunlight that are scattered by the earth’s atmosphere or even like the reflected photons off of an HID light, dimpled reflector. This directional light of LEDs causes more shadowing lower in the plant canopy, reducing PAR when compared to diffused light.

- Natural Variation: Sunlight naturally varies in intensity, direction, and quality throughout the day and across seasons. This variation can stimulate diverse responses in plants, such as changes in growth patterns, flowering times, and leaf orientation, leading to stronger, more resilient plants.

- Vitamin D Synthesis: Sunlight exposure stimulates the production of vitamin D in plants, which is essential for various metabolic processes and overall plant health. While some LEDs can emit UV wavelengths to mimic sunlight, natural sunlight remains the most effective source for promoting vitamin D synthesis in plants.

Negative Environmental Effects on Bees and Wildlife

Although often considered environmentally friendly, LED greenhouse lighting can have negative effects on bees and wildlife. LEDs emit a specific spectrum of light that can disrupt the natural behavior and patterns of insects, including bees. This can interfere with their foraging and navigation abilities, potentially impacting their survival and overall population. Additionally, LEDs, including high intensity LED lights, can attract and disturb other wildlife, such as birds and turtles, that rely on natural darkness for various activities.

LEDs emit light that can have negative impacts on bees and wildlife primarily due to their potential to disrupt natural behaviors and ecological processes. Here are a couple ways in which LEDs, used as supplemental light for plants, can adversely affect bees and other wildlife:

LEDs emit light that can have negative impacts on bees and wildlife primarily due to their potential to disrupt natural behaviors and ecological processes. Here are a couple ways in which LEDs, used as supplemental light for plants, can adversely affect bees and other wildlife:

- Disruption of Pollination: Bees, along with other pollinators, play a crucial role in pollinating flowering plants, including many crops essential for food production. LEDs, particularly those with blue and ultraviolet wavelengths, can interfere with the natural cues that guide pollinator behavior, such as foraging and mating. This disruption may lead to decreased pollination rates, which can ultimately affect plant reproduction and ecosystem stability.

- Altered Circadian Rhythms: Many nocturnal species, including insects, birds, and mammals, rely on natural cycles of light and darkness to regulate their behavior, reproduction, and migration patterns. The introduction of artificial LED lighting, especially in urban and suburban areas, can disrupt these natural circadian rhythms, leading to confusion and disorientation among wildlife. For example, bright LED lights can deter nocturnal insects from foraging or disrupt the navigation of migrating birds.

Although often considered environmentally friendly, they can have negative effects on bees and wildlife. LEDs emit a specific spectrum of light that can disrupt the natural behavior and patterns of insects, including bees. This can interfere with their foraging and navigation abilities, potentially impacting their survival and overall population. Additionally, LEDs can attract and disturb other wildlife, such as birds and turtles, that rely on natural darkness for various activities.

Steep Cost of LED Lights

Not only do LEDs have downsides when it comes to the potential threats to the plant structure as well as nature, but LED lighting systems cost significantly more.

Among the options available, LED fixtures, including high-intensity LED lights, have gained popularity due to their energy efficiency and longevity. However, their initial investment cost remains a significant consideration for farmers and can increase their upfront capital costs for supplemental light for plants by 3-4x when compared to traditional HID lighting.

An average LED light system designed to cover about 16 square feet of crops comes with a price tag of $1,200. This equates to an approximate cost of $75 per square foot.

UbiGro Inner offers an innovative solution that presents a compelling alternative to traditional LED lighting, such as LED greenhouse lighting. UbiGro inner costs are pennies on the dollar compared to LED lighting. At first glance, the stark contrast in pricing might raise skepticism about the efficacy and quality of UbiGro compared to LED lights. However, a closer examination reveals the ingenuity behind this cost-effective solution.

Moreover, the cost savings offered by UbiGro Inner extend beyond the initial purchase price. With its lightweight and easy-to-install design, UbiGro Inner minimizes installation and maintenance expenses, further reducing the total cost of ownership over time. Additionally, the energy-efficient nature of UbiGro translates into lower electricity bills as UbiGro Inner is powered by the sun, making it a financially prudent choice for farmers looking to optimize their operational expenses.

From a sustainability standpoint, UbiGro’s Inner also offers significant advantages. By reducing the reliance on energy-intensive lighting systems, UbiGro contributes to lower carbon emissions and mitigates the environmental footprint of agricultural operations.

With UbiGro’s superior cost-effectiveness, innovative technology, and sustainable attributes, UbiGro presents a promising solution for farmers seeking to optimize productivity while minimizing costs and environmental impact.

What Options are Available?

UbiGro’s innovative greenhouse film solutions enhance the quality of sunlight available to your plants. Utilizing cutting-edge nanotechnology called quantum dots, UbiGro optimizes the sunlight spectrum within your greenhouse, improving plant growth conditions. By converting unused UV and blue photons into beneficial orange, red, and far-red light, UbiGro provides plants with essential elements for thriving without using LED lights or supplemental light for plants.

Designed for adaptability, UbiGro Inner seamlessly integrates into any greenhouse setup, regardless of its type, size, or configuration and UbiGro Cover is now available to replace your existing poly greenhouse covering, whether as a single layer or double-wall system. Whether you opt for the UbiGro Cover for external applications or the UbiGro Inner for internal retrofitting, your plants will benefit from healthier growth and potential yield increases of up to 30%.

UbiGro utilizes a proprietary film embedded with quantum dots, engineered to optimize photosynthetic efficiency by enhancing light distribution and utilization. This technology harnesses the principles of photoluminescence to amplify the available light spectrum, providing plants with the wavelengths they require for growth while minimizing energy waste. The result is a highly efficient and affordable solution that outperforms conventional lighting methods, including high intensity LED lights, in terms of both cost and environmental impact.

UbiGro utilizes a proprietary film embedded with quantum dots, engineered to optimize photosynthetic efficiency by enhancing light distribution and utilization. This technology harnesses the principles of photoluminescence to amplify the available light spectrum, providing plants with the wavelengths they require for growth while minimizing energy waste. The result is a highly efficient and affordable solution that outperforms conventional lighting methods, including high intensity LED lights, in terms of both cost and environmental impact.

Connect with one of our LED greenhouse lighting specialists today to discover more about how UbiGro can revolutionize your greenhouse and natural light experience!

Eric Moody

Eric Moody is UbiQD's Director of UbiGro Sales. Eric has more than 8 years of experience in the horticulture lighting industry, building relationships with greenhouse growers of all sizes and crops on optimal lighting for their growing operation, and most recently managed a North American sales team for PL Light Systems. Overall, Eric has been in sales leadership positions for more than 17 years. Eric brings with him a great understanding of the market and available technologies for growers, greenhouse facilities, and sales leadership.

Share:

Connect With Us

Company

Resources

Hunter McDaniel, PhD

Founder & CEO

Hunter earned a Ph.D. in Materials Science and Engineering at the University of Illinois at Urbana-Champaign, before joining Los Alamos National Laboratory in the Chemistry Division. Ultimately the value proposition of UbiGro is about boosting crop yields and quality without the cost or energy impact of lighting. Hunter has more than fifty publications and patents, and more than 2000 total citations, h-index: 20. Hunter fundamentally believes that novel materials underpin every significant technology advancement, and he is focused on leveraging new materials to have a lasting and sustainable impact.

Damon Hebert, PhD

Director of Agriculture

Damon brings a wide range of experience in agriculture, materials science, spectroscopy, and small business. During his time in Prof. Angus Rockett’s research group at The University of Illinois at Urbana-Champaign (UIUC), Hebert authored a doctoral thesis and multiple papers on the materials science of CIGS semiconductor materials, which is closely related to the materials developed at UbiQD. He also served as a consultant to Nanosolar, a CIGS nanocrystal solar cell manufacturing company. Hebert has industry experience having co-founded Dr. Jolly’s, a leading cultivation and distribution operation in Bend, OR.

Tania Lafaille

Sales Representative

Tania is a UbiGro Sales Representative, with over 7 years of experience in product sales (specifically berries and avocados) covering all of North America and parts of South America. While in agriculture, Tania has cultivated strong relationships with growers and distributors, granting her a unique insight into both perspectives. That understanding, paired with her fierce dedication to results, drives her fun and fiery commitment to her craft. Tania is based in Gilroy, CA.

Tyler Veyna

Sales Representative

Tyler brings 15 years of experience in Greenhouse production and facility management of a wide range of crops in multiple states to the UbiGro team. Based in Salinas, California. “Being a fourth-generation farmer, I look to improve and empower the grower, and with UbiGro, we can do just that.”

Jim Gideon

Sales Manager

Jim Gideon is an UbiGro Sales Manager, with over 25 years of greenhouse industry sales experience covering all of North America. Previously Jim has worked for Green Tek, Plazit-Polygal, Texel, Cherry Creek, and Nexus. He is based in Montgomery, AL, and Jim believes that “light is everything to the grower.”

Eric Moody

Director of Sales

Eric Moody is UbiQD’s Director of UbiGro Sales. Eric has more than 6 years of experience in horticulture lighting industry, building relationships with greenhouse growers of all sizes and crops on optimal lighting for their growing operation, and most recently managed a North American sales team for PL Light Systems. Overall, Eric has been in sales leadership positions for more than 13 years. Eric brings with him a great understanding of the market and available technologies for growers, greenhouse facilities, and sales leadership. Reach Eric by phone at 541-490-6421 or by email at [email protected].

Mike Burrows, PhD

Dr. Michael Burrows is UbiQd’s Vice President of Business Development. His educational background includes a Materials Science doctorate from the University of Delaware and an MBA from Duke University Fuqua School of Business. His career has specialized in the commercialization of novel electronic materials in venture-run programs for different industries including solar, biosensors, and the automotive industry. In both start-up and corporate environments, he has extensive experience in global market development, foraging supply chain partnerships, productization, and brand building. He is currently leading UbiQD’s partnership efforts in luminescent greenhouse technology, smart windows, and security ventures.

Matt Bergern, PhD

Cheif Product Officer

As Chief Product Officer at UbiQD, Dr. Matt Bergren leads the company’s product development efforts, sales, and product manufacturing, including the company’s first commercial agriculture product, UbiGro. He plays a critical role in continuing the company’s path of technology development and vision of powering product innovations in agriculture, clean energy, and security.

He serves as the principal investigator for UbiQD’s contract with NASA, focused on tailoring the solar spectrum for enhanced crop production for space missions. Dr. Bergren’s leadership experience includes serving on the board of directors for the New Mexico Energy Manufacturing Institute, focused on job creation in New Mexico’s energy, and related manufacturing community.