The Green Light Myth: Why Green Light is Essential in Your Plant Spectrum

Highlights:

- UbiGro maintains green light fraction of sunlight

- Other luminescent materials greatly reduce green light

- Green light drives photosynthesis deep in leaf tissue and in dense canopies

Plants use a portion of the solar spectrum for photosynthesis. This portion is the visible light region known as photosynthetically active radiation (PAR), which spans from 400-700 nm. However, not all colors of light within PAR are equally effective at driving crop yields. An emerging strategy to modify the sun’s spectrum and enhance crop growth and yields for greenhouse growers is the passive down-conversion of natural sunlight from short to longer wavelengths (from blue to red). This passive down-conversion process can be achieved using luminescent or glowing materials made of organic and inorganic dyes, phosphors, or quantum dots (QDs).

UbiGro is an agricultural film that utilizes nanotechnology called quantum dots to tailor the sunlight spectrum in a greenhouse by absorbing UV (<400 nm) and blue light (400-500 nm) and converting it to red and orange light (600-700 nm) via a process called photoluminescence. The peak emission color of the QDs is easily tuned by simply changing the size of the nanoparticles in the manufacturing process. This way, a specifically tailored light spectrum can be engineered for a particular crop by selecting a specific size of QD to shift a portion of the sunlight spectrum to the desired color.

While the benefits of shifting some UV/blue light into red/orange light have been fairly well-established, this article focuses on the role of green light. We discuss green light’s role in horticulture and its importance when considering what parts of the sunlight spectrum to absorb and what parts to retain when engineering a tailored spectrum for plants.

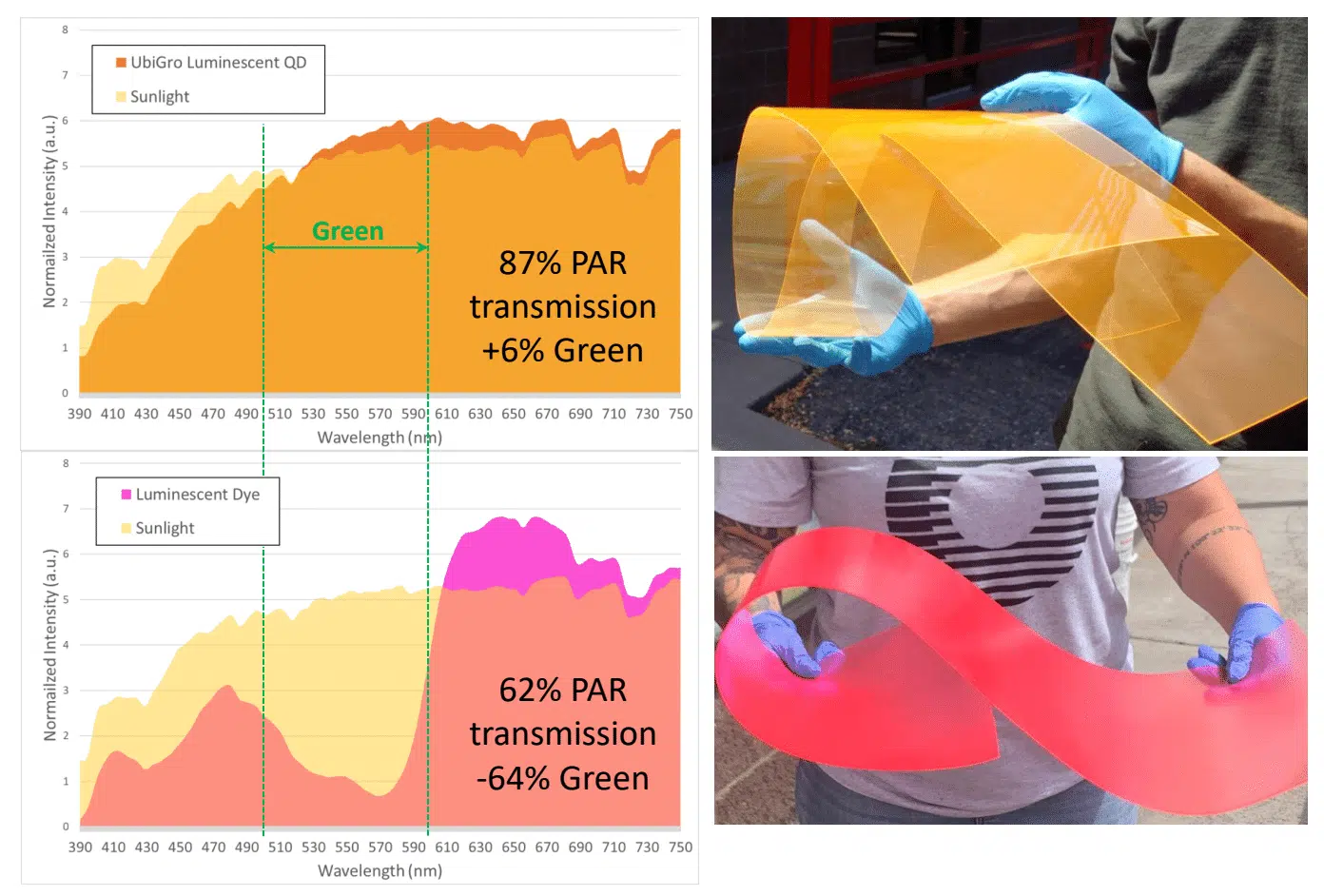

QD Film vs Dye Film

First, let us examine how the UbiGro QD greenhouse film compares to another passive luminescent greenhouse film, which uses a light-altering dye that converts green light to red light. As shown in the figure below, the UbiGro QD film absorbs only UV and blue light, resulting in a relative boost in red light (>10%), peaking at about 600 nm. Importantly, it does not absorb green light; the relative green light fraction is increased by about +6%. The QD film allows 87% total PAR transmission. This results in a bright, orange-colored greenhouse layer.

In contrast, the luminescent dye absorbs mostly in the green portion of the spectrum, 500-600nm, shifting light into the red, peaking at about 640-660 nm. The relative green loss is -64%. The dye film allows 62% total PAR transmission. This results in a darker, magenta-colored (blue+red) greenhouse layer. Compared to the QD film, the dye film allows less PAR transmission and removes green light rather than UV/blue light to achieve the red boost.

So, is green light important? Would we prefer to leave green in the spectrum or convert it to red? The effects of green light on crop production have been studied, and while horticulture scientists continue to learn about the effects of the spectrum of crop growth and development, some general trends have emerged related to green light.

The Green Light Myth

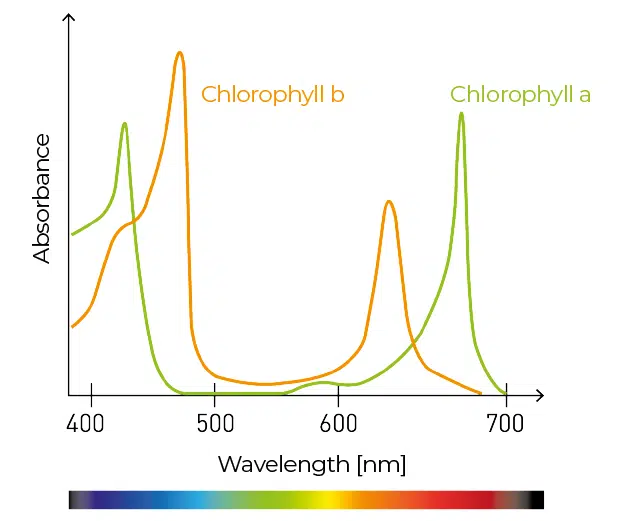

A common misconception that has historically been popular amongst plant biologists is that green light is ineffective in driving photosynthesis in plants.1

The widespread interpretation was that green light is not used efficiently in photosynthesis because chlorophyll has a minimum absorption in the green band. The combination of lower absorption and higher reflection for green light than other colors gives plants their green color. However, lower photosynthetic efficiency for green light has not been shown experimentally. Although green light drives photosynthesis less efficiently than does red light per unit of leaf area, on the whole-plant and whole-canopy levels, green light may increase growth due to changes in vertical light distribution, leaf light acclimation, and canopy architecture.2

Growth Rates

Studies have concluded that a high green light fraction can improve growth rates. A study on lettuce using LEDs showed that supplementing a red and blue LED with green light increased growth rates by 47% while holding PPF constant.5 A green light fraction of 24% was found to be optimal, while too little or too much green light fraction reduced growth rates.

Tissue Penetration

Under high light intensity, blue and red photons are so strongly absorbed in upper cell layers that the bottom of leaf cells are deficient in those colors; but green light, less strongly absorbed by chlorophylls, penetrates deeper into the leaf to drive photosynthesis.6 Green light has been shown to drive leaf photosynthetic rates more efficiently than red or blue light, in a high light background, indicating that whole plant photosynthetic rate could benefit from green light penetration to lower leaf layers.7 The result is that green photons may be as efficient as red and blue photons when provided with a high light intensity.8 In a study where chlorophyll fluorescence was studied in leaf cross sections, it was found that green light penetrated much deeper than red or blue light. 11

Canopy Penetration

While red and blue light drives CO₂ fixation in the upper canopy leaves, it is the green light that penetrates deeper into the canopy and therefore drives CO₂ fixation in lower canopy leaves.9 For high-density canopies, converting blue light to green can provide greater light penetration into the canopy by increasing the fraction of highly penetrating wavelengths.10

Green light has also been shown to be particularly beneficial once the upper canopy as a whole is saturated. 12 Furthermore, the fact that green light provides a more uniform light distribution within the canopy means that the presence of green photons in a spectrum leads to higher overall canopy photosynthetic efficiency. Shade avoidance responses are induced by green photons, working against the decrease in plant size triggered by the presence of blue photons. This can be seen by analyzing the canopy shade spectrum, which exhibits an increase in G:B ratio because blue light is quickly absorbed and green light penetrates the canopy. 13 Green light fraction has also been shown to increase shade avoidance response in lettuce. 14

Artificial Lighting Trends

Despite a history of using only red and blue LEDs, lighting manufacturers such as HelioSpectra (Sweden) and LED Habitats (Santa Fe, NM) have begun incorporating green LEDs into their fixtures for a fuller spectrum. HelioSpectra performed a study on tomatoes that confirmed the impact of green light on the graded size of tomatoes. “On average, 90% of ripened fruits from plants grown under light treatment with a high green percentage were of A class or categorized as large size, and only 70% from plants grown under 5% green treatment reached full size and were categorized A large. Fruits of plants grown under 40% green light were also 18% heavier on average than fruits of plants grown under the 5% green light treatment 15.”

Conclusion

In the realm of plant growth, the role of green light, often underestimated due to its lower efficiency in chlorophyll absorption compared to blue or red light, emerges as crucial when considering its unique properties. The higher reflectance and lower absorption of green light not only facilitate photosynthesis deep within plant tissue but also penetrate dense canopies more effectively, highlighting the benefits of green lights in plant growth. This discovery underscores the importance of green light as a vital component of the optimal light spectrum for plant development, aligning with research on the plant growth light spectrum. This insight has led LED manufacturers to incorporate green light into their latest, most advanced fixtures, recognizing its essential contribution to plant health and productivity. Omitting green light in favor of an exclusive focus on red light could undermine the comprehensive benefits of a full-spectrum approach to plant lighting. UbiGro, aligning with this understanding, preserves a significant fraction of green light, minimizing absorption in the green spectrum. Instead of eliminating green light, UbiGro strategically reduces certain wavelengths, like UV and blue light, enhancing the red/orange light fraction. This adjustment promotes increased growth rates and crop yields, leveraging the full spectrum’s potential to support plant health and productivity, which includes the benefits of green lights in photosynthesis and plant growth.

Source

- Went, Frits W. ‘Experimental control of plant growth.’ Journal of the American Pharmaceutical Association. 1957.

- Elias Kaiser, Kees Weerheim, Rachel Schipper, Janneke A.Dieleman, ‘Partial replacement of red and blue by green light increases biomass and yield in tomato’, Scientia Horticulturae, Volume 249, 30 April 2019, Pages 271-279

- Vogelmann, T.C. and Martin, G. ‘The functional significance of palisade tissue: penetration of directional versus diffuse light.’ Plant, Cell & Environment. 1993.

- Zhen, S. and Bugbee, B. ‘Far-red photons have equivalent efficiency to traditional photosynthetic photons: Implications for redefining photosynthetically active radiation.’ Plant Cell Environ. 2020.

- Kim, Hyeon-Hye; Gions, Gregory D.; Wheeler, Raymond M.; Sager, John C. ‘Green-light supplementation for enhanced lettuce growth under red- and blue-light-emitting diodes.’ HortScience. 2004.

- Sun, Jindong. ‘Green light drives CO2 fixation deep within leaves.’ Plant Cell Physiology. 1998.

- Terashima, Ichiro; Takashi, Fujita; Inoue, Takeshi; Chow, Wah Soon; Oguchi, Riichi. ‘Green light drives leaf photosynthesis more efficiently than red light in strong white light: revisiting the enigmatic question of why leaves are green.’ Plant Cell & Physiology. 2009.

- Jun Liu and Marc W. van Iersel. ‘Photosynthetic Physiology of Blue, Green, and Red Light: Light Intensity Effects and Underlying Mechanisms.’ Frontiers in Plant Science. 2021.

- Sun, Jindong. ‘Green light drives CO2 fixation deep within leaves.’ Plant Cell Physiology. 1998.

- Ooms, Matthew D.; Dinh, Cao Thang; Sargent, Edward H.; Sinton, David. ‘Photon management for augmented photosynthesis.’ Nature Communications. 2015.

- Craig R. Brodersen A C and Thomas C. Vogelmann. ‘Do changes in light direction affect absorption profiles in leaves?’ Functional Plant Biology. 2010.

- Nishio, J. N. ‘Why are higher plants green? Evolution of the higher plant photosynthetic pigment complement.’ Plant, Cell and Environment. 2000.

- Smith, H. L., McAusland, L., and Murchie, E. H. ‘Don’t ignore the green light: exploring diverse roles in plant processes.’ J. Exp. Bot. 2017.

- Johkan, M.; Shoji, K.; Goto, F.; Hahida, S.; Yoshihara, T. ‘Effect of green light wavelength and intensity on photomorphogenesis and photosynthesis in Lactuca sativa.’ Environmental and Experimental Botany. 2012.

- https://www.heliospectra.com/growers-center/green-light-for-tomatoes

Dr. Damon Hebert

Dr. Damon Hebert serves as Director of Agriculture Research for UbiQD, Inc., with a background in solar materials and controlled environment cannabis cultivation. He is an advocate for the use of advanced materials to further the industry’s push towards sustainable farming practices. He can be reached at [email protected].

Dr. Damon Hebert

Dr. Damon Hebert serves as Director of Agriculture Research for UbiQD, Inc., with a background in solar materials and controlled environment cannabis cultivation. He is an advocate for the use of advanced materials to further the industry’s push towards sustainable farming practices. He can be reached at [email protected].

Share:

Connect With Us

Company

Resources

Hunter McDaniel, PhD

Founder & CEO

Hunter earned a Ph.D. in Materials Science and Engineering at the University of Illinois at Urbana-Champaign, before joining Los Alamos National Laboratory in the Chemistry Division. Ultimately the value proposition of UbiGro is about boosting crop yields and quality without the cost or energy impact of lighting. Hunter has more than fifty publications and patents, and more than 2000 total citations, h-index: 20. Hunter fundamentally believes that novel materials underpin every significant technology advancement, and he is focused on leveraging new materials to have a lasting and sustainable impact.

Damon Hebert, PhD

Director of Agriculture

Damon brings a wide range of experience in agriculture, materials science, spectroscopy, and small business. During his time in Prof. Angus Rockett’s research group at The University of Illinois at Urbana-Champaign (UIUC), Hebert authored a doctoral thesis and multiple papers on the materials science of CIGS semiconductor materials, which is closely related to the materials developed at UbiQD. He also served as a consultant to Nanosolar, a CIGS nanocrystal solar cell manufacturing company. Hebert has industry experience having co-founded Dr. Jolly’s, a leading cultivation and distribution operation in Bend, OR.

Tania Lafaille

Sales Representative

Tania is a UbiGro Sales Representative, with over 7 years of experience in product sales (specifically berries and avocados) covering all of North America and parts of South America. While in agriculture, Tania has cultivated strong relationships with growers and distributors, granting her a unique insight into both perspectives. That understanding, paired with her fierce dedication to results, drives her fun and fiery commitment to her craft. Tania is based in Gilroy, CA.

Tyler Veyna

Sales Representative

Tyler brings 15 years of experience in Greenhouse production and facility management of a wide range of crops in multiple states to the UbiGro team. Based in Salinas, California. “Being a fourth-generation farmer, I look to improve and empower the grower, and with UbiGro, we can do just that.”

Jim Gideon

Sales Manager

Jim Gideon is an UbiGro Sales Manager, with over 25 years of greenhouse industry sales experience covering all of North America. Previously Jim has worked for Green Tek, Plazit-Polygal, Texel, Cherry Creek, and Nexus. He is based in Montgomery, AL, and Jim believes that “light is everything to the grower.”

Eric Moody

Director of Sales

Eric Moody is UbiQD’s Director of UbiGro Sales. Eric has more than 6 years of experience in horticulture lighting industry, building relationships with greenhouse growers of all sizes and crops on optimal lighting for their growing operation, and most recently managed a North American sales team for PL Light Systems. Overall, Eric has been in sales leadership positions for more than 13 years. Eric brings with him a great understanding of the market and available technologies for growers, greenhouse facilities, and sales leadership. Reach Eric by phone at 541-490-6421 or by email at [email protected].

Mike Burrows, PhD

Dr. Michael Burrows is UbiQd’s Vice President of Business Development. His educational background includes a Materials Science doctorate from the University of Delaware and an MBA from Duke University Fuqua School of Business. His career has specialized in the commercialization of novel electronic materials in venture-run programs for different industries including solar, biosensors, and the automotive industry. In both start-up and corporate environments, he has extensive experience in global market development, foraging supply chain partnerships, productization, and brand building. He is currently leading UbiQD’s partnership efforts in luminescent greenhouse technology, smart windows, and security ventures.

Matt Bergern, PhD

Cheif Product Officer

As Chief Product Officer at UbiQD, Dr. Matt Bergren leads the company’s product development efforts, sales, and product manufacturing, including the company’s first commercial agriculture product, UbiGro. He plays a critical role in continuing the company’s path of technology development and vision of powering product innovations in agriculture, clean energy, and security.

He serves as the principal investigator for UbiQD’s contract with NASA, focused on tailoring the solar spectrum for enhanced crop production for space missions. Dr. Bergren’s leadership experience includes serving on the board of directors for the New Mexico Energy Manufacturing Institute, focused on job creation in New Mexico’s energy, and related manufacturing community.