+9-13% Boost in Red Romaine Lettuce Trial

AT A GLANCE

- Results

- Crop

- Farm

- Location

Results altogether point to enhanced productivity in a red romaine lettuce cultivar, as measured by dry mass, fresh mass, total leaf area, and light-use efficiency in lettuce farming. These findings highlight significant advancements in the cultivation of lettuce, specifically focusing on the robust growth of red romaine lettuce.

108 plants of Outredgeous’ Red Romaine Lettuce.

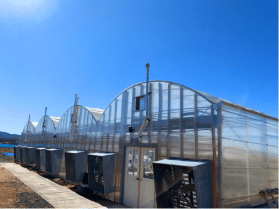

Los Alamos, NM, USA.

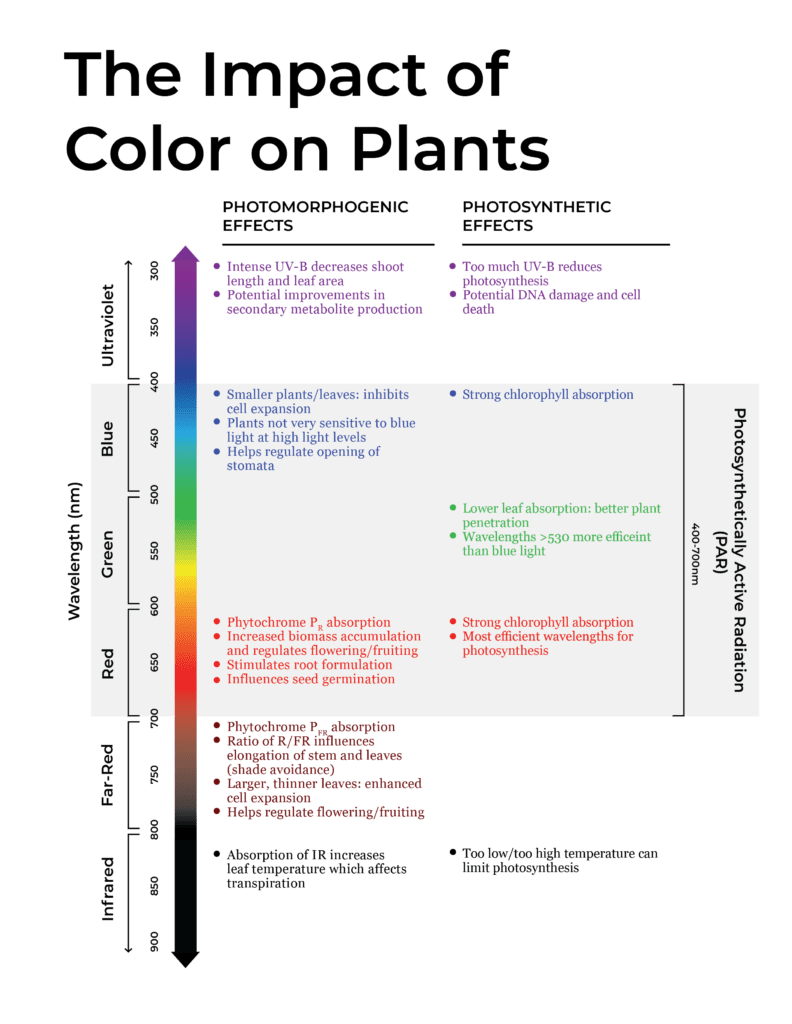

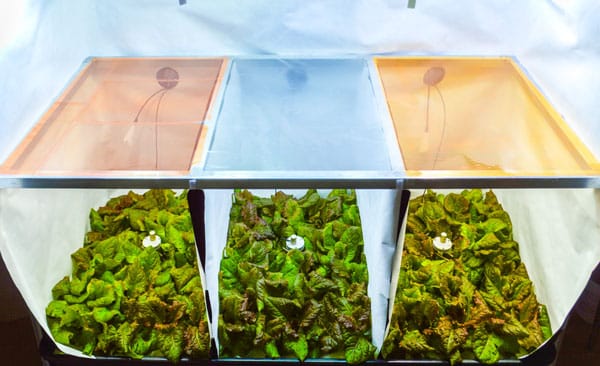

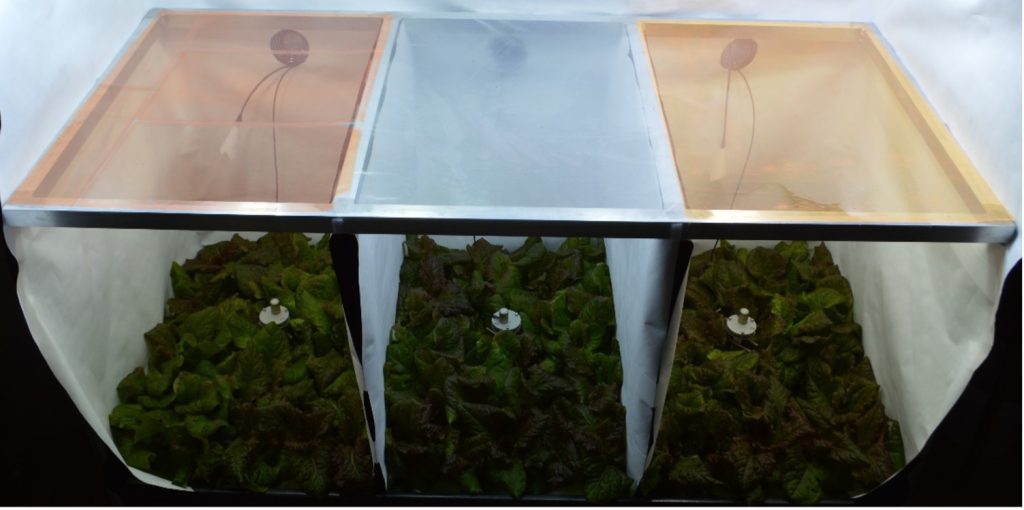

Within each module, ‘Outredgeous’ red romaine lettuce plants were grown hydroponically in deep-water culture in 3.8 cm (1.5 in.) rockwool cubes at a planting density of 55 plants m−2 (5 plants ft−2). The plants were fertigated with a shared, recirculating hydroponic nutrient solution of modified Hoagland’s with pH of 6.1-6.2 and EC of 1.8-1.9 mS cm−1. Sole-source electrical metal-halide lamps were installed above the films to mimic the solar spectrum and provided a uniform light intensity within each module. The lighting regime at plant canopy consisted of a PPFD of ~380 μmol m−2 s−1 and a photoperiod of 14 h/d after germination at 3 DAS, resulting in a daily light integral (DLI) of 17 mol m−2 d−1. The plants were grown at 24/20 °C day/night temperatures with ambient relative humidity and CO2 for 28 days after sowing (DAS). Controlling for all these variables, spectral quality under each film was the only difference in treatment.

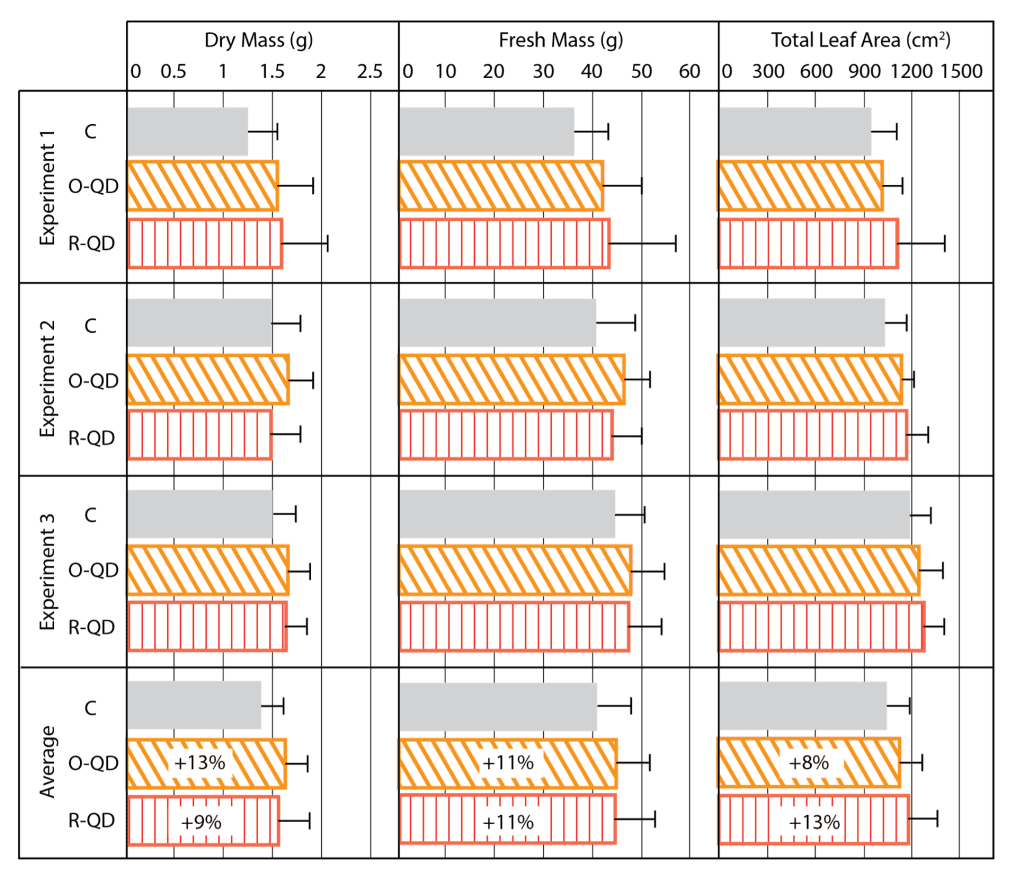

This experimental series included three repeated experiments. Guard rows were planted surrounding all 12 data plants per group per experiment to prevent edge effects from contaminating the data, and results from the 36 data plants per group total were collated and compared. Edible fresh and dry masses as well as total leaf area were measured at the time of harvest (28 DAS), and the results are shown below.

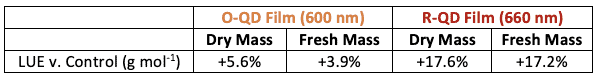

Outliers (+/- 3 standard deviations) were removed from the dataset, and the effect sizes of each metric were calculated to assess the treatment efficacy regardless of variation between experimental repeats. Thus, while the data shows the error bars overlapping between treatments, the results were indeed statistically significantly different. In addition to providing overall average boost in fresh mass, dry mass, and total leaf area, both QD films provided much greater light-use efficiency (LUE, g mol-1) than the Control film as indicated in the table below. Calculated LUE captures the amount of edible biomass produced per light input, so even if light inputs were different, this measure enables direct comparison between treatments. As seen below, the LUE was considerably greater under both QD films than under the Control.

Table

Percentage differences of calculated lighting-use efficiency (LUE) of O-QD and R-QD Films compared with Control on dry mass and fresh mass bases. In summary, these results altogether point to enhanced productivity in a red romaine lettuce cultivar, as measured by dry mass, fresh mass, total leaf area, and light-use efficiency, highlighting advancements in lettuce farming and cultivation of lettuce. By installing QD films within a greenhouse, the solar spectrum can be optimized to provide greater photosynthetic efficiency and thus greater productivity (either by reducing the time required to marketable size or by increasing the mass and area of marketable crops by a grower’s regularly scheduled harvest time) in red romaine lettuce.

To access the free, open-access publication for further information about this study and the results, please visit https://www.nature.com/articles/s42003-020-01646-1.

Acknowledgement

The authors thank California Grow Films for donating the Orca Grow Film used for the module walls and floors and thank Grodan for donating the rockwool cubes used for the root substrates.

Share:

Share: