2023

2022

2021

2020

From Farm to Table: Quantum Dots that Do It All

Q&A: Nanosys, UbiQD Bring Quantum Dots to Agriculture

Greenhouse Technology Boosts Crop Yields Up To 20%

Layer Of Light Helps Plants Get More From The Sun

Hello Tomorrow Deep Tech Finalist

Cannabis Today Podcast – Steve Blank

2019

Harvesting Of Red Light Accelerates Plant Growth

Frost & Sullivan Best Practice Award

Technological Advances Help Optimize Greenhouse Sunlight

10 Killer Agricultural Technologies

Technological Advances Help Optimize Greenhouse Sunlight

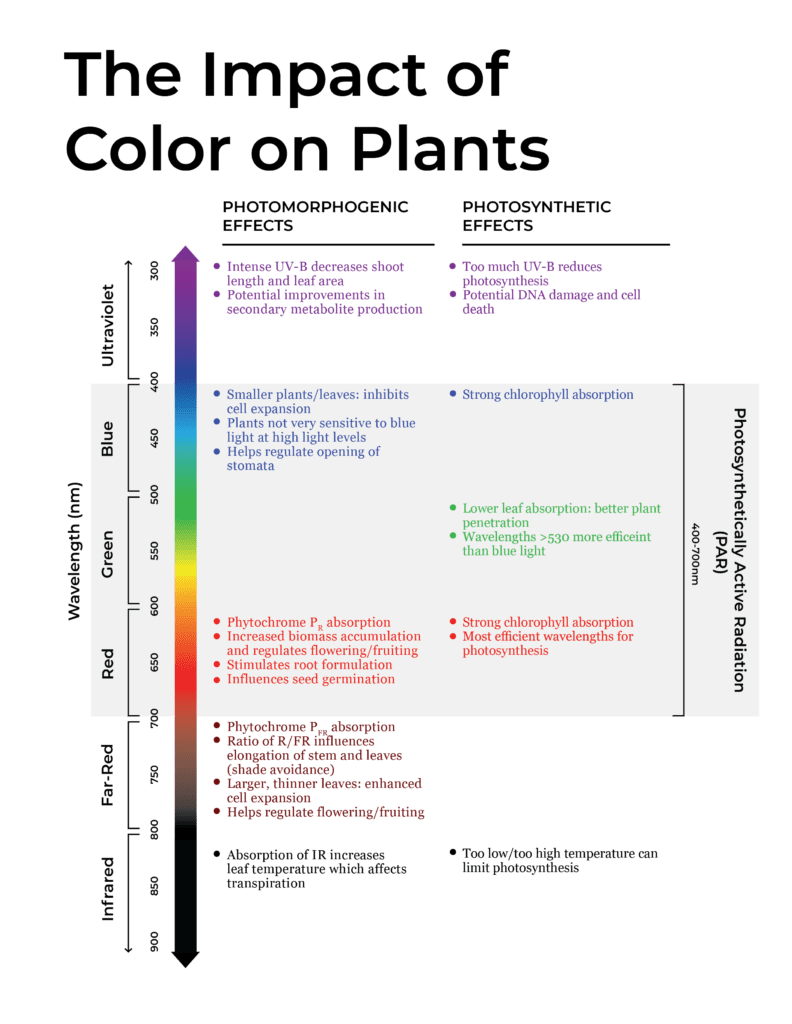

Plants are acutely sensitive to both the quality and quantity of light they receive. While the ideal spectrum for crop growth has not been identified, the horticultural industry agrees that spectrum matters.

Plants use visible light for photosynthesis in the wavelength range of 400 to 700 nanometers, known as photosynthetically active radiation (PAR). Light outside this range is generally not used directly for photosynthesis. Qualitative changes in transmitted radiation inside a greenhouse can modify the architecture and shape of plants, with significant consequences on the value of the crop. Myriad plant responses, including growth and fruit production rates, plant stretching, the color and flavor of food crops, stimulation of terpene and trichome production in cannabis, and the shortening of crop cycles can be regulated by controlling the color spectrum.

The advancement of LED lighting technology has taught growers a lot about spectral quality and how to tune the spectrum for different growth stages. In general, tunable LED manufacturers recommend a redder spectrum for late-stage growth and a bluer spectrum for vegetative growth, with green included for deep-canopy light penetration, driving greater photosynthesis throughout the plant.

It is becoming widely accepted that not all PAR photons are equal with respect to biomass production within the plant. Indoor growers have optimized the spectral control, resulting in increased cannabis yields by as much as 40%. Today’s growers are now using technology to produce individualized light recipes that change throughout the growth cycle in order to achieve efficient plant growth. The days of blue- and red-only LEDs are being replaced by more complex, full-spectrum, tunable fixtures that include a combination of red, far-red, green, blue and white light, in order to ensure efficient plant growth.

In controlling the ratios of different colors, growers are realizing better crop yields and crop quality compared to previous generations. But how can this knowledge from the LED lighting industry help greenhouse growers optimize their sunlight?

Supplemental lighting within a greenhouse offers the same control over spectrum that indoor growers have, but most discussion about sunlight control in greenhouses has been mainly limited to light deprivation, shading, supplemental lighting and photoperiod manipulation. While these are all important aspects of greenhouse growing, they are not addressing the quality of light given to the plants. Several new strategies to control light quality in a greenhouse, ranging from basic to advanced, are being employed by today’s growers.

Greenhouse Materials

The material of choice for conventional greenhouses greatly affects light intensity and light diffusion within the greenhouse. Diffuse light is generally beneficial to plants, allowing more uniformity and deeper light penetration within a canopy. Diffuse light has been shown to increase vegetable production by 5% or more. Treatments or additives to traditional glazing materials offer diffusion options. Tinting, roughening or stippling of glass can diffuse light and improve light transmission at low sun angles.

Most manufacturers of acrylic and polycarbonate sheets offer products with diffusive or antireflective properties. Polyethylene films can include additives that introduce haze, absorb UV or reflect infrared radiation, while reducing overall light levels by as much as 50%. Shade cloths can also be used for diffusion in summer, if light levels are high enough to accommodate the loss of intensity.

Removable, spray-on, photo-selective coatings act as a diffusive tint for greenhouses, transmitting relatively less of a specific color of light and reflecting infrared radiation (heat), reducing greenhouse temperatures. For example, a blue-absorbing coating transmits more red light than blue light, a preferred spectral distribution for some crops, such as cut roses, in particular.

The coatings are suitable for glass, acrylate, polycarbonate and plastic films. Spray-on coatings are a viable option in high light intensity situations where loss of PAR is acceptable. Coatings are typically removed in the winter to allow more PAR to penetrate the greenhouse

Luminescent Materials

A new class of greenhouse materials has emerged recently — luminescent materials that glow in sunlight. These materials convert non-PAR photons (UV, deep blue) to usable photons in order to improve PAR. They also can customize the sun’s spectrum, adjusting it toward a chosen color range. Additionally, luminescent materials can homogenize the solar spectrum across all seasons, bringing a consistent and optimized spectrum to plants regardless of season or latitude.

– Nanotechnology: Luminescent materials come in several options. Recently, the study of solar materials and nanotechnology has led to the development of luminescent films based on semiconductor nanoparticles known as quantum dots (QDs). The QD-containing films “glow,” in that they emit a colored light which depends on the size of the QD. The emitted light can be selected for a specific crop or stage of growth, with red/orange recommended for flowering and green/yellow for vegetative growth.

Luminescent films represent a spectral control strategy best-suited for year-round, high-performance greenhouses. These materials mimic the late summer sun to realize its red/orange color year-round. In the near future, the luminescent materials will be incorporated into traditional greenhouse covering materials such as glass, polycarbonate, polyethylene and acrylic. Initial trials on tomatoes, cucumbers and cannabis have shown biomass yield increases of more than 10%, with improved secondary metabolite formation in cannabis. The major advantage of this type of spectral control is that shading is minimized, typically with losses of less than 15%. In some cases, down-converting UV photons is enough to increase the total intensity of PAR, representing a lossless or even a net gain in PAR transmission.

– Dyes and phosphors: Spectral control films based on color-shifting dyes and phosphors have also been developed. The technology is based on shifting green light to red light using a photoluminescent plastic. Initial trials resulted in yield increases of more than 10% in salad crops. However, real-world testing has revealed stability issues for these films when exposed to high-intensity UV light, humidity and weather conditions. Also, dyes have a spectrum that can be difficult to tune, with red-emitting dyes primarily absorbing green light and transmitting blue light (which could be suboptimal for flowering plants).

Spectral Netting

Spectral netting is a type of knitted greenhouse shade cloth that enables growers to control light dispersion and accelerate growth rates by filtering sunlight (subtracting colors) to modify the spectrum. They are produced using unique proprietary chromatic additives. They are often used on fields or orchards for protection against hail, wind, sunburn and flying animals. The amount of shading spectral nets provide can reduce overall light intensity by 18-75% and therefore are suitable for plants that can handle the reduced light intensity, such as fruit orchards and ornamental plants. Spectral netting has been shown to increase stem lengths and weights, increase the number of flowering stems and influence the timing of flowering.

Wavelength Selective Mulches

Another strategy for spectral control in a greenhouse is the use of photo-selective mulches, which selectively reflect certain colors. New colors of mulches that are currently being investigated — red, yellow, blue, gray and orange — have distinct optical characteristics and reflect different colors into the lower canopy, thereby affecting plant growth and development.

While still unproven in a controlled setting, many gardeners claim that the specific colors of their mulch do have an influence over the success of their planting. Growers prefer red mulch for strawberries, tomatoes and cannabis, claiming the color reflects more sun back toward the plants and encourages more vigorous flowering.

Conclusion

The quality of the spectrum of sunlight used in greenhouses can be controlled by various methods to improve crop yields and quality. Depending on crop type and sun intensity, some options make more sense than others. With many growers looking to improve yields with expensive and energy-consuming technologies such as under-canopy supplemental lighting, spectral control of sunlight using passive, long-term technology that optimizes the spectrum of sunlight represents a major step toward bringing modern greenhouse agriculture into sustainability, reducing electricity usage and providing more crops at a reduced cost.

Share: