How Luminescent Materials Are Different Than Filters

Filters

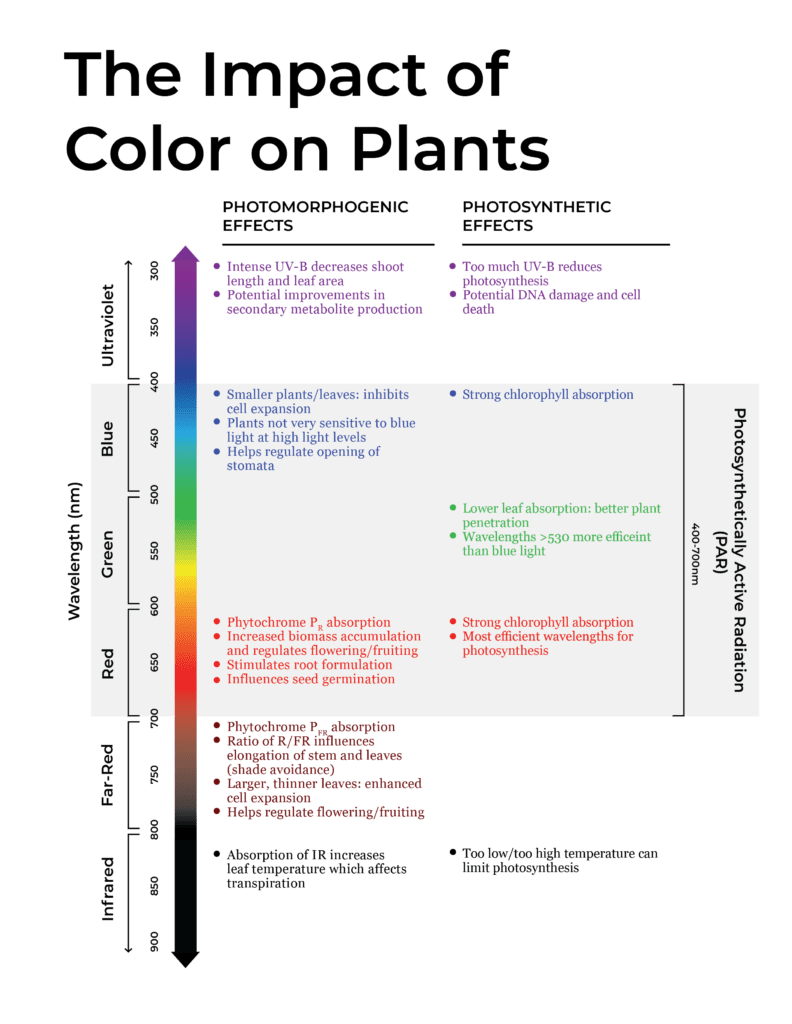

Luminescent materials, such as those used in luminescent films, can enhance the functionality of colored light filters, especially in advanced greenhouse lighting solutions. These filters work by selectively absorbing or transmitting certain wavelengths of light. They are composed of a material infused with pigments or dyes—potentially including luminescent compounds—that absorb specific wavelengths of light, allowing others to pass through. When integrated into greenhouse lighting, luminescent materials can modify the light spectrum in beneficial ways, potentially improving plant growth by optimizing the light that plants absorb.

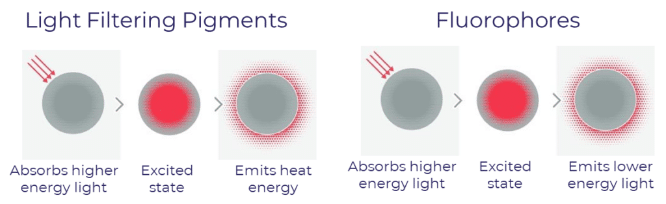

The process involves the plant absorbing light and converting it into heat energy, which is then dissipated into the environment. This conversion is facilitated by the pigments or dyes in the filter, which may vibrate at frequencies similar to those of desired light wavelengths, such as red light. In some cases, luminescent materials can absorb light at one wavelength and re-emit it at another, further tailoring the light spectrum reaching the plants. As a result, the filter can be designed to transmit only specific wavelengths of light, like red light, which is crucial for photosynthesis.

The efficiency of this light conversion and the amount of light lost through a colored filter incorporating luminescent materials depend on several factors. These include the type, thickness, and the wavelengths of the filtered light, as well as the properties of the luminescent compounds used. Typically, the range of light loss through these filters is between 40-80%. However, the introduction of luminescent materials into the filters can potentially reduce this loss by converting non-useful wavelengths into those more beneficial for plant growth. The color intensity of the filter, influenced by the concentration of pigments, dyes, and luminescent materials, directly correlates with the amount of light intensity lost or transformed, offering an innovative approach to managing light in greenhouse environments for advanced agricultural applications.

For example, a deep red filter will absorb more light than a light pink filter. The thickness of the filter also plays a role in how much light intensity is lost. Thicker filters absorb more light than thinner filters, as they have a greater volume for the light to interact with.

The amount of light intensity lost is also influenced by the specific wavelengths of light being filtered. For example, if a green filter filters out blue light, less light intensity will be lost than if the same green filter is used to filter out red light, as green filters are less effective at absorbing red light.

It is important to note that while some light intensity is lost through a colored filter, the transmitted light’s quality (or color spectrum) is changed. For example, a blue filter will reduce overall light intensity but enhance the concentration of exposure to blue light in the spectrum, which can benefit specific applications such as plant growth or photography.

Figure 1. Filters absorb light and convert it to heat. Fluorophores absorb light and convert it to lower energy light or a redder color.

Luminescent Materials and Greenhouse Advanced Lighting Solutions

Luminescent materials, also known as fluorophores, are unique in their ability to emit light through processes such as fluorescence or phosphorescence. These materials stand out because when exposed to light, they absorb the energy and re-emit it at a longer wavelength (lower energy), which is why they’re often referred to as “glowing” materials or “light conversion materials.” This characteristic makes them invaluable in advanced lighting solutions, particularly in the context of greenhouses.

Innovative applications of luminescent materials, including luminescent films, in greenhouse coverings can significantly enhance light management. Quantum dots, dyes, and phosphors are examples of colored luminescent materials that can be integrated into these coverings. By doing so, it is possible to modify the spectrum of light that penetrates the greenhouse, which in turn can influence plant growth and development positively.

One of the groundbreaking applications of these materials is the use of quantum dots to fine-tune the sunlight’s spectral composition to meet the specific needs of various plants. By adjusting the size and composition of the quantum dots, their absorption and emission spectra can be tailored. This allows for the precise control over which wavelengths of light are absorbed and emitted, optimizing the light environment for enhanced plant growth.

For those interested in exploring the intricate relationship between light and plant growth, our blog, “Light Interaction with Plants: Reflection, Emission, and Absorption,” offers a deeper dive. It elucidates how luminescent materials, particularly luminescent films, are revolutionizing greenhouse advanced lighting solutions, heralding a new era of precision agriculture.

Similarly, dyes and phosphors can create light filters that selectively absorb or transmit certain wavelengths of light. However, because filters aren’t luminescent, their total light intensity loss is more significant than their luminescent counterparts. Coating a greenhouse cover with a layer of these materials makes it possible to control the amount and quality of light that enters the greenhouse, providing a more optimal environment for plant growth.

Overall, colored luminescent materials have great potential for greenhouse covers, as they offer a flexible and customizable way to manipulate the light environment to promote plant growth and development without using electricity.

Dr. Damon Hebert

Dr. Damon Hebert serves as Director of Agriculture Research for UbiQD, Inc., with a background in solar materials and controlled environment cannabis cultivation. He is an advocate for the use of advanced materials to further the industry’s push towards sustainable farming practices. He can be reached at [email protected].

Connect With Us

Company

Resources

Hunter McDaniel, PhD

Founder & CEO

Hunter earned a Ph.D. in Materials Science and Engineering at the University of Illinois at Urbana-Champaign, before joining Los Alamos National Laboratory in the Chemistry Division. Ultimately the value proposition of UbiGro is about boosting crop yields and quality without the cost or energy impact of lighting. Hunter has more than fifty publications and patents, and more than 2000 total citations, h-index: 20. Hunter fundamentally believes that novel materials underpin every significant technology advancement, and he is focused on leveraging new materials to have a lasting and sustainable impact.

Damon Hebert, PhD

Director of Agriculture

Damon brings a wide range of experience in agriculture, materials science, spectroscopy, and small business. During his time in Prof. Angus Rockett’s research group at The University of Illinois at Urbana-Champaign (UIUC), Hebert authored a doctoral thesis and multiple papers on the materials science of CIGS semiconductor materials, which is closely related to the materials developed at UbiQD. He also served as a consultant to Nanosolar, a CIGS nanocrystal solar cell manufacturing company. Hebert has industry experience having co-founded Dr. Jolly’s, a leading cultivation and distribution operation in Bend, OR.

Tania Lafaille

Sales Representative

Tania is a UbiGro Sales Representative, with over 7 years of experience in product sales (specifically berries and avocados) covering all of North America and parts of South America. While in agriculture, Tania has cultivated strong relationships with growers and distributors, granting her a unique insight into both perspectives. That understanding, paired with her fierce dedication to results, drives her fun and fiery commitment to her craft. Tania is based in Gilroy, CA.

Tyler Veyna

Sales Representative

Tyler brings 15 years of experience in Greenhouse production and facility management of a wide range of crops in multiple states to the UbiGro team. Based in Salinas, California. “Being a fourth-generation farmer, I look to improve and empower the grower, and with UbiGro, we can do just that.”

Jim Gideon

Sales Manager

Jim Gideon is an UbiGro Sales Manager, with over 25 years of greenhouse industry sales experience covering all of North America. Previously Jim has worked for Green Tek, Plazit-Polygal, Texel, Cherry Creek, and Nexus. He is based in Montgomery, AL, and Jim believes that “light is everything to the grower.”

Eric Moody

Director of Sales

Eric Moody is UbiQD’s Director of UbiGro Sales. Eric has more than 6 years of experience in horticulture lighting industry, building relationships with greenhouse growers of all sizes and crops on optimal lighting for their growing operation, and most recently managed a North American sales team for PL Light Systems. Overall, Eric has been in sales leadership positions for more than 13 years. Eric brings with him a great understanding of the market and available technologies for growers, greenhouse facilities, and sales leadership. Reach Eric by phone at 541-490-6421 or by email at [email protected].

Mike Burrows, PhD

Dr. Michael Burrows is UbiQd’s Vice President of Business Development. His educational background includes a Materials Science doctorate from the University of Delaware and an MBA from Duke University Fuqua School of Business. His career has specialized in the commercialization of novel electronic materials in venture-run programs for different industries including solar, biosensors, and the automotive industry. In both start-up and corporate environments, he has extensive experience in global market development, foraging supply chain partnerships, productization, and brand building. He is currently leading UbiQD’s partnership efforts in luminescent greenhouse technology, smart windows, and security ventures.

Matt Bergern, PhD

Cheif Product Officer

As Chief Product Officer at UbiQD, Dr. Matt Bergren leads the company’s product development efforts, sales, and product manufacturing, including the company’s first commercial agriculture product, UbiGro. He plays a critical role in continuing the company’s path of technology development and vision of powering product innovations in agriculture, clean energy, and security.

He serves as the principal investigator for UbiQD’s contract with NASA, focused on tailoring the solar spectrum for enhanced crop production for space missions. Dr. Bergren’s leadership experience includes serving on the board of directors for the New Mexico Energy Manufacturing Institute, focused on job creation in New Mexico’s energy, and related manufacturing community.